|

NELSON'S MKII WIND TUNNEL

HOME | AUTOMOTIVE | BLUEPLANET | ELECTRIC CARS | ENERGY | INSURANCE | INDEX | SOLAR CARS |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

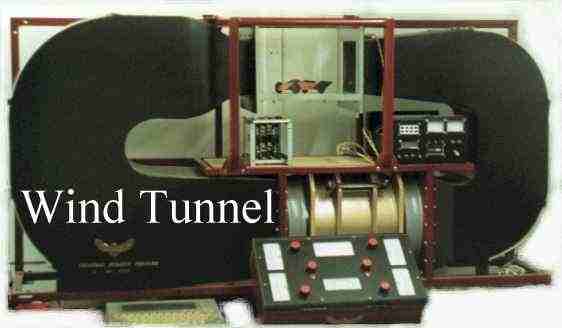

The designer of BE1, 2 & Blueplanet Ecostar, Ace, built a series of small wind tunnels to refine the aerodynamics of his vehicles. The tunnel shown below was the latest. It could accommodate 1/25th scale models. If you look closely a model of the BE1 is seen in the transparent observation module.

ACE - "build your own instruments"

Ace says: "A basic understanding of fluid dynamics is essential for every vehicle designer. Whether you are building a land speed record car, or a hyper efficient town buggy, you must have an idea of the forces acting upon the vehicle to achieve best results. Unfortunately, this is a highly specialised engineering field and somewhat of a black art."

"I decided to build my first wind tunnel just to get the feel for it. I'm glad I did. The first plywood tunnel I built was an open ended affair and took only a few days at a cost of £50." (Note 1980s prices)

"The closed circuit model shown on this page had a tubular steel support frame and welded aluminum tunnel walls. It took around three months to build, with a lot of delving into electronics, thereafter, at a total cost of £6,000." (Note: 1990s prices)

Nelson's Mk2 wind tunnel - electronic measurement

Strain gauges provided measurement of drag, lift and down-force. A rotating table was incorporated so vehicle models could be tested in side wind conditions. Air temperature and wind speed were also monitored and smoke could be trailed over models to visualize airflow, to highlight problem areas. This tunnel could fit comfortably on an office desk. It measured just 60" x 40" x 15". Being a closed circuit design it was not unbearably noisy in operation.

A wind tunnel is a complex piece of engineering. The Wright Brothers were the first inventors to use such a tool to compile lift and drag tables for various wing shapes. It is much more difficult to design a balance to measure lift and down-force on each wheel of a vehicle. When working at such a small scale, accuracy of measurement is essential. Fortunately, electronics come to the rescue, with compensated amplifiers providing multiplication of movement up to a thousand.

Wind tunnel instrument display - Lift/down force, drag and wind speed

The key component of any wind tunnel is the fan assembly. Take a look at the propeller and motor above. In is mounted on eight springs to reduce vibration. The whole fan module is then positioned on rubber mounts, which in turn channel vibration through a plywood frame. The net effect is to pass the vibration through materials with different natural frequencies, so acting as a vibration filter, much like coils and capacitors are used to filter out unwanted frequencies in Hi Fi speaker systems. Lead weights are also employed to give mass to the base frame unit.

In fluid dynamics, a streamline is a line which is everywhere tangent to the velocity of the flow. This can be contrasted with a pathline, which is the trajectory that an imaginary infinitesimally small point would make if it followed the flow of the fluid in which it was embedded, and a streakline, which is the current location of all fluid particles that have passed through a particular spatial point in the past. In steady (time-independent) flow, the streamlines, pathlines, and streaklines coincide. A scalar function whose contours define the streamlines is known as the streamfunction.

Streamlines are frame-dependent. That is, the streamlines observed in one inertial reference frame are different from those observed in another inertial reference frame. For instance, the streamlines in the air around a aircraft wing are defined differently for the passengers in the aircraft than for an observer on the ground. When possible, fluid dynamicists try to find a reference frame in which the flow is steady, so that they can use experimental methods of creating streaklines to identify the streamlines. In the aircraft example, the observer on the ground will observe unsteady flow, and the observers in the aircraft will observe steady flow, with constant streamlines.

By definition, streamlines defined at a single instant in a flow do not intersect. They cannot begin or end inside the fluid. A region bounded by streamlines is called a stream tube. Because the streamlines are tangent to the flow velocity, fluid that is inside a stream tube must remain forever within that same stream tube.

Knowledge of the streamlines can be useful in fluid dynamics. For example, Bernoulli's principle, which expresses conservation of mechanical energy, is only valid along a streamline. Also, the curvature of a streamline is an indication of the pressure change perpendicular to the streamline. The instantaneous center of curvature of a streamline is in the direction of increasing pressure, and the magnitude of the pressure gradient can be calculated from the curvature of the streamline.

Nelson's Blueplanet Ecostar - wind tunnel model

Engineers often use dyes in water or smoke in air in order to see streaklines, and then use the patterns to guide their design modifications, aiming to reduce the drag. This task is known as streamlining, and the resulting design is referred to as being streamlined. Streamlined designs, like steam locomotives, streamliners and human bodies are often esthetically pleasing to the eye.

The Streamline Moderne style, an 1930s and 1940s offshoot of Art Deco, brought flowing lines to architecture and design of the era. The canonical example of a streamlined shape is a chicken egg with the blunt end facing forwards. This shows clearly that the curvature of the front surface can be much steeper than the back of the object. Most drag is caused by eddies in the fluid behind the moving object, and the objective should be to allow the fluid to slow down after passing around the object, and regain pressure, without forming eddies.

The same terms have since become common vernacular to describe any process that smooths an operation. For instance, it is common to hear references to streamlining a business practice, or operation.

WIND TUNNEL HISTORY

WIND TUNNEL TECHNICAL

A wind tunnel is a research tool developed to assist with studying the effects of air moving over or around solid objects.

Air is blown or sucked through a duct equipped with a viewing port and instrumentation where models or geometrical shapes are mounted for study. Various techniques are then used to study the actual airflow around the geometry and compare it with theoretical results, which must also take into account the Reynolds number and Mach number for the regime of operation.

For example:

A vertical wind tunnel is a recreational facility for indoor skydiving.

LINKS:

Wind Tunnels of NASA (NASA SP-440, 1981)

JOYSTICK-CAR | WIND-TUNNEL | WIND TUNNEL DETAILS

CHASSIS

LOADING-SERVO CARTRIDGE

MOTORS JOYSTICK-CAR

WIND-TUNNEL

RENEWABLE ELECTRICITY

Solar power from micro generation is now a growing industry as many Youtube videos are demonstrating. As these conversions and new builds gain in popularity electric vehicles will also gain favour, especially for households generating excess energy, which they could get better value from by using for transport. Electricity used in this way might reduce transport costs by up to 200%. So provide a higher quality of life with lesser environmental damage.

If buying an EV, it would make sense to have the latest future proof technology, such as battery cartridge exchange built into the vehicle, for self servicing, or exchanges at local stores or cooperatives. This technology exists but has not yet been incorporated in production vehicles.

When EVs become available with cartridge refueling, it would make sense to have in place at least a few service stations to cater for eventual demand. The technology would thus be in place when it is needed. Such a move when it is implemented will greatly reduce carbon dioxide build up in the atmosphere and ease the transition from oil based economies to abundant clean energy.

THE CHICKEN AND EGG SITUATION

If there were service forecourts to cater for battery cartridge exchange, that might in turn persuade motor manufacturers to produce vehicles with the system. This is a classic chicken and egg situation. Who should do what first.

Given the scale of the problem, it might be prudent for every corporation involved in the industry to at least investigate the potential that any emerging technology might offer for the future on mankind, which is after all the future of their company and eventual profits for their shareholders.

MODEL MAKING STAGES

Steps 1. Mark out your plywood and cut formers Step 2. Assemble plywood formers Step 3. Fill formers with foam and shape Step 4. Coat foam plug with plaster Step 5. Sand, add detail mouldings and prime Step 6. Paint finished model

ENERGY GENERATING-DISTRIBUTION UTILITIES

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LOADING-SERVO | CARTRIDGE | MOTORS | JOYSTICK-CAR WIND-TUNNEL | WIND TUNNEL DETAILS

This is the kind of result you can expect from your wind tunnel - a super slippery 350+ mph electric streamliner. This particular car is charged by solar power, making it probably the world's fastest solar powered electric land speed record car. She also has battery cartridge exchange built in, for instant refueling.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The content of this website is copyright © and design copyright 1991 and 2013 Electrick Publications. All rights reserved. The bluebird logo & names Bluebird and Blue Max are registered trademarks. The BE2 and BE3 vehicle configurations are registered designs ®. All other trademarks are hereby acknowledged. Max Energy Ltd is an environmental educational charity working for world peace.

EDUCATION | E. CYCLES | SOLAR CAR TEAMS | SOLARNAVIGATOR

|