|

EPOXY RESIN

|

||||||||||

|

Epoxy or polyepoxide is a thermosetting epoxide polymer that cures (polymerizes and crosslinks) when mixed with a catalyzing agent or "hardener". Most common epoxy resins are produced from a reaction between epichlorohydrin and bisphenol-A. The first commercial attempts to prepare resins from epichlorohydrin occurred in 1927 in the United States. Credit for the first synthesis of bisphenol-A based epoxy resins is shared by Dr. Pierre Castan of Switzerland and Dr. S.O. Greenlee in the United States in 1936. Dr. Castan's work was licensed by Ciba, Ltd. of Switzerland and Ciba went on to become one of the 3 major epoxy resin producers worldwide.

The epoxy business of Ciba was spun-off and later sold in the late 1990s and is now the advanced materials business unit of Huntsman Corporation of the United States. Dr. Greenlee's work was for a company called Devoe-Reynolds of the United States. Devoe-Reynolds was a player in the early days of the epoxy resin industry, but later sold its business to Shell Chemical (now Hexion, formerly Resolution Polymers and others).

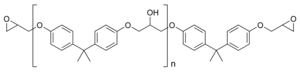

Structure of unmodified epoxy prepolymer. n denotes the number of polymerized subunits and is in the range from 0 to about 25

Industry

Today the epoxy industry amounts to more than US $5 billion in North America and about US $15 billion world-wide. It is made up of approximately 50–100 manufacturers of basic or commodity epoxy resins and hardeners of which the big 3 are Hexion (formerly Resolution Performance Products, formerly Shell Development Company; whose epoxy tradename is "Epon"), The Dow Chemical Company (tradename "D.E.R."), & Huntsman Corporation's Advanced Materials business unit (formerly Vantico, formerly Ciba Specialty Chemical; tradename "Araldite"). The other 50+ smaller epoxy manufacturers primarily produce epoxies only regionally (not world-wide), produce epoxy hardeners only, produce specialty epoxies, or produce epoxy modifiers.

These commodity epoxy manufacturers mentioned above typically do not sell epoxy resins in a form usable to much smaller end users, so there is another group of companies that purchase epoxy raw materials from the major producers and then compounds (blends, modifies, or otherwise customizes) epoxy systems out of these raw materials. This class of companies is typically known as "formulators". The vast majority of the epoxy systems sold are produced by these smaller formulators and they account for greater than 60% of the dollar value of the overall epoxy market. There are hundreds of ways that these formulators can modify epoxies — by adding mineral fillers (ex. talc, silica, alumina, etc.), by adding flexibilizers, viscosity reducers, colorants, thickeners, accelerators, adhesion promoters, etc. These modifications are made to reduce costs, to improve performance, and to improve processing convenience. As a result a typical formulator sells dozens, hundreds, or even thousands of formulations — each carefully tailored to the requirements of a particular application or market.

The applications for epoxy based materials are extensive and include coatings, adhesives and composite materials such as those using carbon fiber and fiberglass reinforcements, (although polyester, vinyl ester, and other thermosetting resins are also used for glass-reinforced plastic). The chemistry of epoxies and the range of commercially available variations allows cure polymers to be produced with a very broad range of properties. In general, epoxies are known for their excellent adhesion, chemical and heat resistance, good to excellent mechanical properties and very good electrical insulating properties, but almost any property can be modified (for example silver-filled epoxies with good electrical conductivity are widely available even though epoxies are typically electrically insulating).

Epoxies find significant use in many applications including the following:

Paints and coatings

Examples include powder coatings for washers, driers and other "white goods". Fusion Bonded Epoxy Powder Coatings (FBE) are extensively used for corrosion protection of steel pipes and fittings used in the oil & gas industry, potable water transmission pipelines (steel), concrete reinforcing rebar etc. Epoxy coatings are also widely used as primers to improve the adhesion of automotive and marine paints especially on metal surfaces where corrosion (rusting) resistance is important. Metal cans and containers are often coated with epoxy to prevent rusting especially for foods like tomatoes that are acidic. Epoxy resins are also used for high performance & decorative flooring applications especially terrazzo flooring, Chip Flooring [1] and colored aggregate flooring [2].

Special epoxy adhesives are strong enough to withstand extreme hydrodynamic force transferred from a surfboard fin to the fin mount. This epoxy is capable of curing underwater. The blue epoxy on left is curing.

Adhesives

Epoxy adhesives are a major part of the class of adhesives called "structural adhesives" or "engineering adhesives" (which also includes polyurethane, acrylic, cyanoacrylate, and other chemistries.) These high performance adhesives are used in the construction of airplanes, automobiles, bikes, golf clubs, skis, snow boards, and many other applications where high strength bonds are required. Epoxy adhesives can be developed that meet almost any application. They are exceptional adhesives for wood, metal, glass, stone, and some plastics. They can be made flexible or rigid, transparent or opaque/colored, fast setting or extremely slow. Epoxy adhesives are almost unmatched in heat and chemical resistance among common adhesives. In general, epoxy adhesives cured with heat will be more heat- and chemical-resistant than the same formulation cured at room temperature.

Moulding

Epoxies represent some of the most versatile resins available to the composite manufacturer. Generally, in all categories of work, the builder/repairer will realize the greatest degree of bond strength, waterproofing and toughness with well formulated epoxies. New generation MAS Epoxies are VOC free and have curing systems which are phenol free (representing a safe step forward for all resin users).

Atmospheric moisture is of little concern, as blush-free MAS systems allow builders and repairers to laminate and bond with little or no surface preparation between applications as long as mix ratios are followed and mixing is adequate. Shrinkage of MAS epoxies is below .03% eliminating prerelease. In the case where a part, originally manufactured utilizing polyester or vinylester, has yielded to strain and cracked, a well-reinforced epoxy repair will tenaciously hold to the substrate with 2000 psi strrength (vinylester: 500 psi). Many high strain repair areas and lightweight parts must flex and strain without micro fracturing.

MAS resins have the ability to flex with the fibers while maintaining permanence and adhesion. Whether a part or repair is made of wood, carbon, Kevlar, fiberglass, core material or hybrids of the above, MAS Epoxies will wet and permanently stick to the composite. Just a quick note: one composite manufacturer recently eliminated a peroxide cured and extremely pricey custom-formulated aerospace adhesive (fancy packaging and all) with a standard MAS product. The benefits included elimination of VOC's from the assembly area, reduced price, increased strength, and elimination of shrink problems from the bond line. When MAS Epoxies are used for a chemical resistant barrier (barrier coating) the finished coating system has excellent resistance to water uptake (below .5%) and the user can be confident that subsequent finishes will stick to the new epoxy and the epoxy will stick to the surface.

New generation MAS epoxies feature many of the advantages of low viscosity and accurately tailored gel and cure times. Permanent repairs and the highest quality custom aerospace construction have been enjoying the advantages of epoxies since the sixties. MAS brings these advantages to the builder and repairer at room temperatures, and we're gearing up for more surprises in the 21st century.

Industrial tooling and composites

Epoxy systems are also used in industrial tooling applications to produce molds, master models, laminates, castings, fixtures, and other industrial production aids. This "plastic tooling" replaces metal, wood and other traditional materials and generally improves the efficiency and either lowers the overall cost or shortens the lead-time for many industrial processes. Epoxies are also used in producing fiber reinforced or composite parts. They are more expensive than polyester resins and vinyl ester resins, but generally produce stronger more temperature resistant composite parts.

Electrical systems and electronics

Epoxy resin formulations are also important in the electronics industry and are used in many parts of electrical systems. In electrical power generation, epoxy systems encapsulate or coat motors, generators, transformers, switchgear, bushings, and insulators. Epoxy resins are excellent electrical insulation materials and they protect electrical components from short circuiting, dust, humidity and other environmental factors that could damage the electrical equipment. In the electronics industry, epoxy resins are the primary resin used in overmolding integrated circuits and transistors, and making printed circuit boards. The largest volume type of circuit board — an "FR-4 board" — is nothing but a sandwich of several layers of glass cloth bonded together into a composite by an epoxy resin. Epoxy resins are also used in bonding copper foil to circuit board substrates and are a major component of the solder mask used on many circuit boards.

SOUTHERN ANGEL - From a block of cured foam an artist has rough shaped what is to be the ocean angel. This sculpture will be captured in epoxy resin and glass woven roving. Another identical version will be made in carbon fibre to save weight. Copyright © photographs 16 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FORM - In this picture you can see a figurehead emerge from the block of foam in the picture above. There is still a way to go where, after the 2nd stage detail is carved, this has to be locked solid using epoxy resin and woven glass cloth. The next step is to reinforce the angel's wing tips with several layers of fibreglass matt, followed by a polyurethane core and epoxy resin sealing. The 3rd stage detailing is just as time consuming using epoxy putty to fill any blemishes prior to surface preparations and a coat of 2-pack varnish ready for gilding. Copyright © photographs 16 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ANGEL WINGS - Two layers of woven roving are cut for each wing of a large statute with overlaps that will be folded under the wing where possible for extra strength. It is difficult to get so many curves in one laminating session. In this case, several sessions were necessary. Copyright © photographs 19 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

MERMAID TAILFIN - Two layers of woven glass fibre cloth are cut to size for the mermaid tail fin of the Ocean Angel sculpture. Copyright © photographs 19 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

Consumer and marine applications

Epoxies are sold in many hardware stores, typically as two component kits. They are also sold in many boat shops as repair resins for marine applications. Epoxies typically are not the outer layer of a boat because they are negatively affected by long term exposure to UV light. But they are often used during boat repair and assembly and then are over coated with polyester gel coats or marine varnishes that protect the epoxies from UV exposure. Polyester thermosets typically use a ratio of at least 10:1 of resin to hardener (or "catalyst") whereas epoxy materials typically use a lower ratio of from 5:1 down to 1:1. Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden more abruptly.

The classic epoxy reference guide is the "Handbook of epoxy resins" by Henry Lee and Kris Neville. Originally issued in 1967, it has been re-issued repeatedly and still gives an excellent overview of the technology. For basic installation tips please see www.epoxy.com/install.htm.

Aerospace applications

In the aerospace industry, epoxy is used to stabilise a fiber matrix. Usually, these fibers are made of one or any of the following: glass, carbon, kevlar, boron, etc. On a smaller scale, epoxies are also used as a structural glue. Materials like wood, and others that are seemingly 'low-tech', are glued together with epoxy resin. One example, in this case a homebuilt aircraft, would be the RJ.03 IBIS. This design is based on a classic wooden lattice structured fuselage and a classic wooden spar, internally stiffened with foam and completely covered with plywood. With the exception of the plywood covering on the wings, everything is glued with epoxy resin.

Chemistry

When the epoxy is mixed with the appropriate catalyst, the resulting reaction is exothermic and the oxygen on the epoxy monomers are "flipped" if you will. As this occurs throughout the epoxy, a matrix is formed which has a very high stress tolerance and is what "glues" the materials together.

Possible health risks

Both epichlorohydrin and bisphenol A are suspected endocrine disruptors.

According to the GreenPeace 2006 April Report "OUR REPRODUCTIVE HEALTH AND CHEMICAL EXPOSURE"[3], Bisphenol A can cause:

COMPOSITE DIRECTORY

LINKS:

|

||||||||||

|

The

content of this website is copyright © and design copyright 1991 and

2018 Electrick Publications. All rights reserved. The bluebird

logo |

||||||||||