|

POLYESTER RESIN

|

||||||||||

|

HOME | INDEX | AUTOMOTIVE | BLUEBIRD | ELECTRIC CARS | E. CYCLES | SOLAR CARS |

||||||||||

|

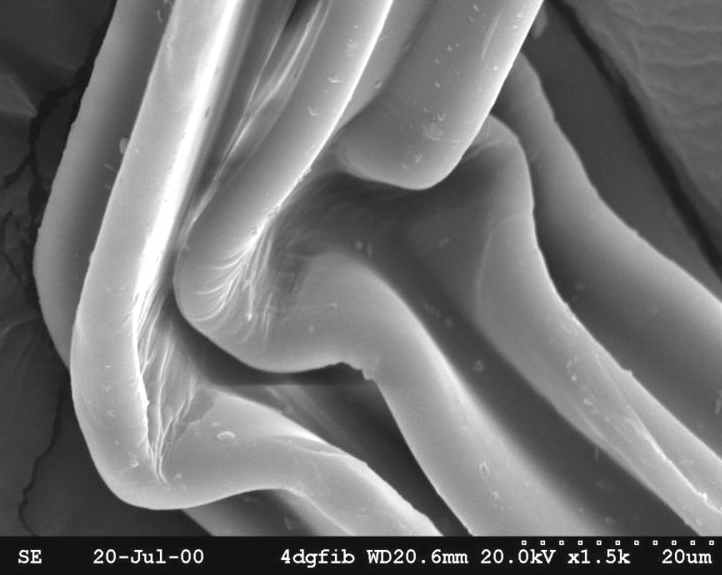

Polyester is a category of polymers, or, more specifically condensation polymers, which contain the ester functional group in their main chain. Usually, polyester refers to cloth woven from polyester fiber. Polyester clothing is generally considered to have a "less natural" feeling to it compared to natural fibers. Polyester fibers are often spun together with fibers of cotton, producing a cloth with some of the better properties of each.

Although polyesters do exist in nature (e.g., in the Cutin of the Plant Cuticle), polyester generally refers to the large family of synthetic polyesters (plastics) which includes polycarbonate and above all polyethylene terephthalate (PET). PET is one of the most important thermoplastic polyesters.

Extreme care with fire around polyester should be exercised, as polyester is extremely flammable and flames can leap from a match to polyester at a range of at least three inches (7.5 cm).

Applications

Polyester is the most widely used manufactured fiber in the United States. Woven fabrics are used for apparel and home furnishings. These include bed sheets, bedspreads, curtains and draperies. Polyester used in knitted fabrics include shirts and blouses. Fiberfill is also used to stuff pillows, comforters and cusion padding.

The first synthetic polyester, glycerine phthalate, was used in the First World War for waterproofing. Natural polyesters have been known since around 1830.

Polyesters are used to make bottles, films, liquid crystal displays, holograms, filters, dielectric film for capacitors, film insulation for wire and insulating tapes.

Liquid crystalline polyesters are among the first industrially used liquid crystalline polymers. In general they have extremely good mechanical properties and are extremely heat resistant. For that reason, they can be used as an abradable seal in jet engines.

Thermosetting polyester resins are commonly used as casting materials, fiberglass laminating resins, and non-metallic auto-body fillers. In such applications, polymerization and cross-linking are initiated through an exothermic reaction involving an organic peroxide, such as methyl ethyl ketone peroxide or benzoyl peroxide.

Resin

Polyesters are one of the least expensive resins available to the FRP boat builder utilizing female tooling in the form of a mold. Polyester has the advantage of being extremely inexpensive when compared with other thermoset resins i.e. vinylesters and epoxies. If the upside is cheap pricing, the down side includes poor adhesions, high water absorption, high shrinkage, and high VOC's. Polyester resins are only compatible with fiberglass fibers. Polyester is best suited for applications insensitive to weight and do not require high adhesion or fracture toughness. For instance if a simple inexpensive solid fiberglass part must be fabricated in open tooling in one operation and requires no secondary bonding. If shape accuracy is not critical, resistance to water is of no concern, and ventilation of the workspace is excellent, then polyester's a great candidate.

Polyesters historically exhibit poor performance in the areas of adhesion and elongation, rendering the finished part prone to micro cracking and secondary bond failures. These parameters become more important when we consider adhering dissimilar materials within the same part or welding any materials that are not the usual fiberglass strand substrate. Finished polyester hulls are still suffering from osmotic blistering when untreated by an epoxy barrier coating against water. Boat yards are filled with hull and superstructures suffering from massive areas of core disbonding or delamination resulting from an adhesive mismatch with the industry at large (i.e. depending on polyester as an adhesive).

Properties

Polyester has excellent durability, abrasion resistance, tenacity and high elongation. The fiber also has high appearance retention, dimensional stability, elastic recovery and excellent resiliency. It remains very strong when it is wet. However, polyester ranks very poorly in comfort and absorbency.

Filament fibers can be bright, delustered, or have high or low tenacity. Staple fibers can range in deniers as well as the degree in which they pill.

Aesthetics

The fiber blends well with other fibers and maintains a natural look. Polyester can be engineered to be very similar in appearance and hand to wool, linen and silk.

The low absorbency causes the fabric to be very uncomfortable. This can be improved through blending it with other fibers. Static can be controlled through additives and changes in the compound.

Environmental impact

The impact is very similar to that of nylon. Polyester is extensively recycled, and less pollution is created when the recycled fibers are reengineered than when new ones are created.

History

Terylene was the first polyester fiber and was produced in England. It was brought to the U.S. in 1951 by DuPont under the trade name Dacron.

Synthesis

Synthesis of polyesters is generally achieved by a polycondensation reaction. See "condensation reactions in polymer chemistry".

COMPOSITE DIRECTORY

LINKS:

A taste for adventure capitalists

Solar Cola - a healthier alternative

|

||||||||||

|

AUTOMOTIVE | EDUCATION | SOLAR CAR RACING TEAMS | SOLAR CAR RACING TEAMS | SOLAR CARS |

||||||||||

|

The

content of this website is copyright © and design copyright 1991 and

2006 Electrick Publications and NJK. All rights reserved. The bluebird

logo |

||||||||||