|

CARBON FIBER

|

||||||||||

|

HOME | INDEX | AUTOMOTIVE | BLUEBIRD | ELECTRIC CARS | E. CYCLES | SOLAR CARS |

||||||||||

|

Carbon fiber can refer to carbon filament thread, or to felt or woven cloth made from those carbon filaments. By extension, it is also used informally to mean any composite material made with carbon filament; for more on that application, see graphite-reinforced plastic.

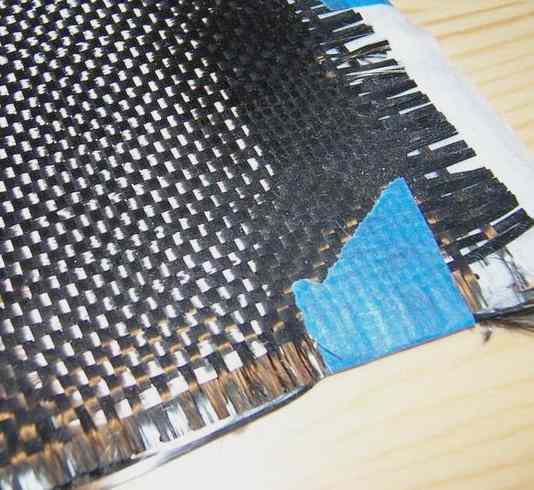

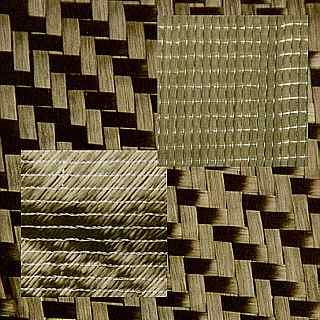

Cloth of woven carbon filaments Synthesis

Each carbon filament is made out of long, thin sheets of carbon similar to graphite. A common method of making carbon filaments is the oxidation and thermal pyrolysis of polyacrylonitrile (PAN), a polymer used in the creation of many synthetic materials. Like all polymers, polyacrylonitrile molecules are long chains, which are aligned in the process of drawing fibres. When heated in the correct fashion, these chains bond side-to-side, forming narrow graphene sheets which eventually merge to form a single, jelly roll-shaped filament. The result is usually 93-95% carbon. Lower-quality fibre can be manufactured using pitch or rayon as the precursor instead of PAN. The carbon can become further enhanced, as high modulus, or high strength carbon, by heat treatment processes. Carbon heated in the range of 1500-2000 °C (carburizing) exhibits the highest tensile strength (820,000 psi or 5,650 MPa or 5,650 N/mm²), while carbon fiber heated from 2500 to 3000 °C (graphitizing) exhibits a higher modulus of elasticity (77,000,000 psi or 531 GPa or 531 kN/mm²).

Textile

There are several categories of carbon fibers: standard modulus (240 GPa) , intermediate modulus (300 GPa), high modulus (> 300 GPa). The tensile strength of different yarn types varies between 2000 and 7000 MPa.

Precursors for carbon fibers are PAN and pitch. In former times rayon was also used as a precursor and still is for certain specialized applications.

Carbon fiber filament yarns are used in serveral proccessing techniques: the direct use is for: prepregging, filament winding, pultrusion, weaving, braiding etc.

These filaments are stranded into a thread. Carbon fiber thread is rated by the number of filaments per thread, in thousands. For example, 3K (3,000 filament) carbon fiber is 3 times as strong as 1K carbon fiber, but is also 3 times as heavy. This thread can then be used to weave a carbon fiber cloth. The appearance of this cloth generally depends on the size of thread and the weave chosen. Carbon fiber is naturally a glossy black but recently colored carbon fiber has become available.

Uses

Carbon fiber is most notably used to reinforce composite materials, particularly the class of materials known as graphite reinforced plastic. This class of materials is used in high-performance vehicles, sporting equipment, and other demanding mechanical applications; a more thorough discussion of these uses, including composite lay-up techniques, can be found in the carbon fibre composite article.

Close up of woven carbon filaments

Non-polymer materials can also be used as the matrix for carbon fibres. Due to the formation of metal carbides (i.e., water-soluble AlC), bad wetting by some metals, and corrosion considerations, carbon has seen limited success in metal matrix composite applications; however, this can be improved by proper surface treatment, eg. for carbon-aluminium MMCs a vapor deposition of titanium boride on the fibers is often employed. Reinforced carbon-carbon (RCC) consists of carbon fiber-reinforced graphite, and is used structurally in high-temperature applications, such as the nose cone and leading edges of the space shuttle.

The fiber also finds use in filtration of high-temperature gases, as an electrode with high surface area and impeccable corrosion resistance, and as an anti-static component in high-performance clothing.

Some string instruments, such as violins and cellos, use carbon fiber reinforced composite bows. This is an alternative to the more common wooden bows.

Many high end frames for road bikes and mountain bikes are made of carbon fiber reinforced composite. Also, many road bikes made of aluminum have carbon fiber reinforced composite seat posts, handlebars and forks for reduced weight.

It is also widely used to enhance the look of automobiles and reduce weight. Many of the "tuner" style cars have carbon fiber hoods to reduce weight from a stock 28 lb hood to an 8 lb hood. Another use is in the increasingly popular hobby of RC cars, many high-end kits come with many carbon fiber parts due to their light weight and attractive appearance. Ex: Mugen MBX-5,Jammin X1CR PRO

Carbon fiber is also used by skateboard companies to make strong lightweight skateboards for all types of skating, mainly downhill speedboarding. It is also used in many composite longboards to stiffen an otherwise very flexible board.

Carbon fibre is also used on racing yachts and rowing boats. Its use has allowed boat builders to produce stiffer and lighter boats. Carbon, and other artificial fibres, has replaced more traditional laminated wooden constructions.

COMPOSITE DIRECTORY

LINKS:

A taste for adventure capitalists

Solar Cola - a healthier alternative

|

||||||||||

|

AUTOMOTIVE | EDUCATION | SOLAR CAR RACING TEAMS | SOLAR CAR RACING TEAMS | SOLAR CARS |

||||||||||

|

The

content of this website is copyright © and design copyright 1991 and

2006 Electrick Publications and NJK. All rights reserved. The bluebird

logo |

||||||||||