|

|

||||||||

|

HOME | INDEX | AUTOMOTIVE | BLUE PLANET BE3 | ELECTRIC CARS | ENERGY | FORMULA E | NEWS | SOLAR CARS |

||||||||

|

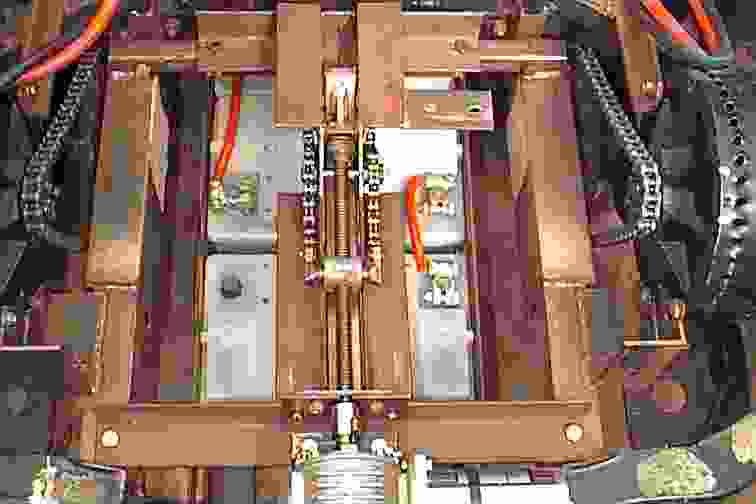

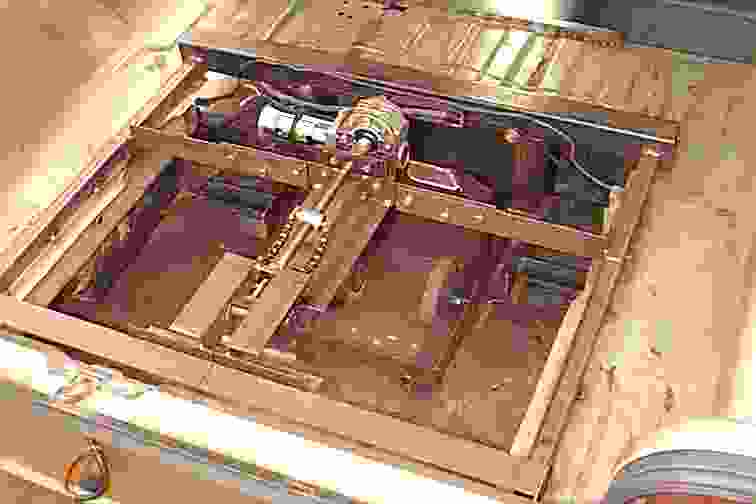

The Ecostar DC50 featuring the Bluebird™ battery cartridge exchange system

What is the most advanced battery available today for EVs? At this point it time that could very well be the lithium based range of batteries.

A lithium-ion battery (sometimes Li-ion battery or LIB) is a family of rechargeable battery types in which lithium ions move from the negative electrode to the positive electrode during discharge, and back when charging. Chemistry, performance, cost, and safety characteristics vary across LIB types. Unlike lithium primary batteries (which are disposable), lithium-ion electrochemical cells use an intercalated lithium compound as the electrode material instead of metallic lithium.

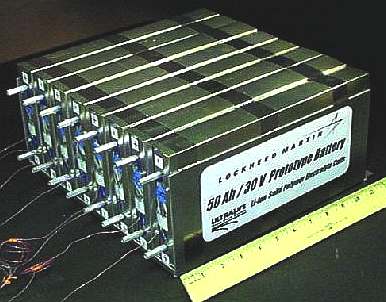

Lockheed lithium ion battery for NASA

During discharge, lithium ions Li+ carry the current from the negative to the positive electrode, through the non-aqueous electrolyte and separator

diaphragm.

Cylindrical 18650 lithium iron phosphate cell before closing

The three primary functional components of a lithium-ion battery are the anode, cathode, and electrolyte. The anode of a conventional lithium-ion cell is made from carbon, the cathode is a metal oxide, and the electrolyte is a lithium salt in an organic

solvent.

Li-ion cells are available in various formats, which can generally be divided into four

groups:

The lack of case gives pouch cells the highest energy density; however, pouch cells (and prismatic cells) require an external means of containment to prevent expansion when their state-of-charge (SOC) level is

high.

Varta lithium-ion battery, Museum Autovision, Altlussheim, Germany

Lithium batteries were first proposed by M.S. Whittingham, now at Binghamton University, while working for Exxon in the

1970s. Whittingham used titanium(II) sulfide as the cathode and lithium metal as the anode.

Nissan Leaf's lithium-ion battery pack

In 1991, Sony and Asahi Kasei released the first commercial lithium-ion battery.

The three participants in the electrochemical reactions in a lithium-ion battery are the anode, cathode, and electrolyte.

Nokia Li-ion battery for powering a mobile phone

Electrode material Average potential difference Specific capacity Specific energy

Note that both advantages and disadvantages depend on the materials and design that make up the battery. This summary reflects older designs that use carbon anode, metal oxide cathodes, and lithium salt in an organic solvent for the electrolyte.

Optima ACP TZERO tubular plate lead acid batteries

Wide variety of shapes and sizes efficiently fitting the devices they power.

Much lighter than other energy-equivalent secondary batteries.

High open circuit voltage in comparison to aqueous batteries (such as lead acid, nickel-metal hydride and nickel-cadmium).[46] This is beneficial because it increases the amount of power that can be transferred at a lower current.

Self-discharge rate of approximately 5-10% per month, compared to over 30% per month in common nickel metal hydride batteries, approximately 1.25% per month for Low Self-Discharge NiMH batteries and 10% per month in nickel-cadmium batteries. According to one manufacturer, lithium-ion cells (and, accordingly, "dumb" lithium-ion batteries) do not have any self-discharge in the usual meaning of this word. What looks like a self-discharge in these batteries is a permanent loss of capacity (see Disadvantages). On the other hand, "smart" lithium-ion batteries do self-discharge, due to the drain of the built-in voltage monitoring circuit.

Components are environmentally safe as there is no free lithium metal.

Charging forms deposits inside the electrolyte that inhibit ion transport. Over time, the cell's capacity diminishes. The increase in internal resistance reduces the cell's ability to deliver current. This problem is more pronounced in high-current applications. The decrease means that older batteries do not charge as much as new ones (charging time required decreases proportionally).

The internal resistance of standard (Cobalt) lithium-ion batteries is high compared to both other rechargeable chemistries such as nickel-metal hydride and nickel-cadmium, and LiFePO4 and lithium-polymer cells. Internal resistance increases with both cycling and age. Rising internal resistance causes the voltage at the terminals to drop under load, which reduces the maximum current draw. Eventually increasing resistance means that the battery can no longer operate for an adequate period.

If overheated or overcharged, Li-ion batteries may suffer thermal runaway and cell rupture.[56] In extreme cases this can lead to combustion. Deep discharge may short-circuit the cell, in which case recharging would be

unsafe. To reduce these risks, Lithium-ion battery packs contain fail-safe circuitry that shuts down the battery when its voltage is outside the safe range of 3–4.2 V per

cell. When stored for long periods the small current draw of the protection circuitry itself may drain the battery below its shut down voltage; normal chargers are then ineffective. Many types of lithium-ion cell cannot be charged safely below 0°C. These devices occupy useful space inside the cells, add additional points of failure and irreversibly disable the cell when activated. They are required because the anode produces heat during use, while the cathode may produce oxygen. These devices and improved electrode designs reduce/eliminate the risk of fire or explosion. Specifications and design

Specific energy density: 150 to 250 W·h/kg (540 to 900

kJ/kg) Because lithium-ion batteries can have a variety of cathode and anode materials, the energy density and voltage vary accordingly.

The charging procedures for single Li-ion cells, and complete Li-ion batteries, are slightly different.

A Li-ion battery (a set of Li-ion cells in series) is charged in 3 stages:

2.

Balance (not required once a battery is balanced)

The increasing demand for batteries has led vendors and academics to focus on improving the power density, operating temperature, safety, durability, charging time, output power, and cost of LIB solutions.

A lithium-ion battery from a laptop computer

Avoid deep discharge and instead charge more often between uses, the smaller the depth of discharge, the longer the battery will last.

Li-ion batteries require a battery management system to prevent operation outside each cell's safe operating area (over-charge, under-charge, safe temperature range) and to balance cells to eliminate SOC mismatches, significantly improving battery efficiency and increasing overall

capacity. As the number of cells and load currents increase, the potential for mismatch also

increases. There are two kinds of mismatch in the pack: state-of-charge (SOC) and capacity/energy ("C/E") mismatch. Though SOC is more common, each problem limits pack capacity (mA·h) to the capacity of the weakest cell.

Lithium-ion batteries can rupture, ignite, or explode when exposed to high temperature. Short-circuiting a battery will cause the cell to overheat and possibly to catch fire. Adjacent cells may then overheat and fail, possibly causing the entire battery to ignite or rupture. In the event of a fire, the device may emit dense irritating

smoke.

In March 2007, Lenovo recalled approximately 205,000 batteries at risk of explosion. In August 2007, Nokia recalled over 46 million batteries at risk of overheating and

exploding. One such incident occurred in the Philippines involving a Nokia N91, which uses the BL-5C

battery.

In January 2008, the United States Department of Transportation ruled that passengers on commercial aircraft could carry lithium batteries in their checked baggage if the batteries are installed in a device. Types of batteries affected by this rule are those containing lithium, including Li-ion, lithium polymer, and lithium cobalt oxide chemistries. Lithium-ion batteries containing more than 25 grams (0.88 oz) equivalent lithium content (ELC) are exempt from the rule and are forbidden in air

travel. This restriction greatly reduces the chances of the batteries short-circuiting and causing a

fire.

Researchers are working to improve the power density, safety, recharge cycle, cost and other characteristics of these batteries.

LINKS:

"Rechargeable Li-Ion OEM Battery Products". Panasonic.com. "Panasonic Develops Higher-Capacity Li-Ion Cells; Application of Silicon-based Alloy in Anode". greencarcongress.com The effect of PHEV and HEV duty cycles on battery and battery pack performance (PDF). 2007 Vapor-grown carbon fiber anode for cylindrical lithium batteries. Journal of Power Sources Battery Types and Characteristics for HEV ThermoAnalytics, Inc., 2007 Ballon, Massie Santos (14 October 2008). "Electrovaya, Tata Motors to make electric Indica". cleantech.com. Cleantech Group Thackeray, Thomas, and Whittingham (March 2000). Mixed Conductors for Lithium Batteries. mrs.com; Materials Research Society MSDS: National Power Corp Lithium Ion Batteries (PDF). tek.com; Tektronix Inc., 7 May 2004 Battery Management Systems for Large Lithium-Ion Battery Packs page 2 "Cell boards for various cell formats". Elithion.com Battery Management Systems for Large Lithium-Ion Battery Packs page 234 "USPTO search for inventions by "Goodenough, John"". Patft.uspto.gov US 4304825, Basu; Samar, "Rechargeable battery", issued 8 December 1981, assigned to Bell Telephone Laboratories Gholamabbas Nazri, Gianfranco Pistoia (2004). Lithium batteries: science and ... - Google Books. Springer Voelcker, John (September 2007). Lithium Batteries Take to the Road IEEE Spectrum. US 4668595, Yoshino; Akira, "Secondary Battery", issued 10 May 1985, assigned to Asahi Kasei Padhi, A. K. (1997). "Phospho-olivines as positive-electrode materials for rechargeable lithium batteries". Electrochem. Society Editors (6 March 2008). "In search of the perfect battery" (PDF). The Economist Staff (November 2003) (PDF). Lithium Ion technical handbook. Gold Peak Industries Ltd. "Impedance Analysis of Silicon Nanowire Lithium Ion Battery Anodes" (PDF) C. K. Chan; X. F. Zhang, Y. Cui (2007). "High Capacity Li-ion Battery Anodes Using Ge Nanowires" (PDF) Liquid Electrolyte Systems for Advanced Lithium Batteries (PDF). cheric.org; Chemical Engineering Research Information Center "A123 M1 cell specifications". Battery Management Systems for Large Lithium-Ion Battery Packs page 12 Buchmann, Isidor (200804). "Choosing a battery that will last". Isidor Buchmann (CEO of Cadex Electronics Inc.) Battery Management Systems for Large Lithium-Ion Battery Packs page 229 Buchmann, Isidor (September 2006). "BatteryUniversity.com: How to prolong lithium-based batteries" Buchmann, Isidor (February 2003). "Advanced battery analyzers". Isidor Buchmann "Lithium-ion Battery Charging Basics". PowerStream Technologies AeroVironment achieves electric vehicle fast-charge milestone avinc.com; AeroVironment, 30 May 2007 "Charging Lithium-ion Batteries". batteryuniversity.com. "The 3 charging stages". Liionbms.com. http://liionbms.com/php/wp_charging_stages.php Battery Management Systems for Large Lithium Ion Battery Packs section 6.2.3 Kevin Jost [ed.] (October 2006). Tech Briefs: CPI takes new direction on Li-ion batteries (PDF) Voelcker, John (September 2007). Lithium Batteries Take to the Road. IEEE Spectrum. Loveday, Eric (23 April 2010). "Hitachi develops manganese cathode, could double life of li-ion batteries". Nikkei (29 November 2009). Nissan On Track Nickel Manganese Cobalt Li-ion Cell for 2015 Green Car Congress Bulkeley, William M. (26 November 2005). "New Type of Battery Offers Voltage Aplenty, at Premium" (2 November 2005) A123Systems Launches Higher-Power, Faster Recharging Green Car Congress. "Imara Corporation website". Imaracorp.com. http://www.imaracorp.com. Retrieved 8 October 2011. Battery Company Says Its Technology Boosts Hybrid Battery Performance Green Car Advisor; Edmunds Inc. "A multifunctional 3.5 V iron-based phosphate cathode for rechargeable batteries" "A Research First: Lithium Air Battery Development (Press Release)". 17 November 2009 "Vanadium Modified LiFePO4 Cathode for Li-ion Batteries" Acceptance of the First Grid-Scale, Battery Energy Storage System" (Press release) 21 November 2008 Marty Ozols (11 November 2009). Altair Nanotechnologies Power Partner - The Military "Microsoft PowerPoint - 061125 Altair EDTA Presentation". Altairnano.com. Blain, Loz (2 November 2007). "Subaru doubles the battery range on its electric car concept". gizmag. "Li-Ion Rechargeable Batteries Made Safer". Nikkei Electronics Asia. 29 January 2008. "gatech.edu". http://www.mse.gatech.edu. Palca, Joe (6 April 2009). Hidden Ingredient In New, Greener Battery: A Virus. npr.org; National Public Radio. Zandonella, Catherine (11 April 2009). "Battery grown from "armour plated" viruses". New Scientist Bullis, Kevin (28 September 2006). "Powerful Batteries That Assemble Themselves". technologyreview "Bad Virus Put to Good Use". Clark School of Engineering, University of Maryland. 6 December 2010. "Self-Assembled Nanocomposites Boost Lithium-Ion Battery Anodes". Nature Materials http://www.gatech.edu/newsroom/release.html?nid=54920. "New Nanowire Battery Holds 10 Times The Charge Of Existing Ones". Science Daily. 20 December 2007. http://www.sciencedaily.com/releases/2007/12/071219103105.htm. "Interview with Dr. Cui, Inventor of Silicon Nanowire Lithium-ion Battery Breakthrough". GM-Volt. "Metal hydrides for lithium-ion batteries". Nature Materials 7 (11): 916–921. 2008NatMa...7..916O "Laboratory of the Prof. Gleb Yushin". Nano-tech.gatech.edu. 31 August 2011. "Deformations in Si−Li Anodes Electrochemical Alloying in Nano-Confined Space". American Chemical Society (30 September 2011). "A Simple Way to Boost Battery Storage". Technology Review Welcome to Ener1. Ener1 (Press release). Archived from the original 8 July 2006. EnerDel Technical Presentation (PDF). EnerDel Corporation. 29 October 2007. Bullis, Kevin (22 June 2006). Higher-Capacity Lithium-Ion Batteries Technology Review "How to Prolong Lithium-based Batteries". Battery University "Modelling Lithium-ion cells, Analysis Lithium-Ion Battery Degradation during Thermal Aging" (PDF). http://www.electrochem.org/dl/ma/204/pdfs/0253.PDF About Battery Management Systems White Paper - CCCV chargers: a false sense of security. ELithion LLC. Commercial Power (9 September 2006). "Safety handling guidelines for Lithium Batteries" (PDF). http://marine.rutgers.edu. University. "Safety Last". The New York Times. http://www.nytimes.com/2006/09/01/opinion/01cringely.html Nokia issues BL-5C battery warning, offers replacement. Wikinews. 14 August 2007. Staff (27 July 2007). Nokia N91 cell phone explodes Mukamo - Filipino News (blog). "Dell Recalls Lithium Batteries". Chemical and Engineering News:11; American Chemical Society Dell laptop explodes at Japanese conference. The Inquirer. "Kyocera Launches Precautionary Battery Recall" (Press release). Kyocera Wireless. 28 October 2004. "Safe Travel". Safetravel.dot.gov. U.S. Department of Transportation. 1 January 2008 "U.S. Department of Transportation revises lithium battery rules press release". Little Guy Media. http://www.robgalbraith.com/bins/content_page.asp?cid=7-9206-9211 Prohibitions - 6.3.12 - Dangerous, offensive and indecent articles (PDF). Hong Kong. December 2009 International Mail > FAQs > Goods/Services: Shipping a Laptop Japan Post Service Co. Ltd. http://arstechnica.com/science/news/2011/08/new-solid-state-compound-lithium-ion-batteries.ars Melody Voth (6 December 2010). "Battery Booster". http://pubs.acs.org/cen/email/html/8849bus1.html "What Are Batteries, Fuel Cells, and Supercapacitors?" (PDF). Chemical Review 104 (104): 4245. doi:10.1021/cr020730k. http://pubs.acs.org/doi/pdf/10.1021/cr020730k. Retrieved 25 July 2010. Lithium batteries at the Open Directory Project "The Future of Electric Vehicles on Lithium Availability". Journal of Energy Security

Automotive Development

Battery cartridges are the way to go for road cars. Lithium Ion batteries offer a much higher energy density and are ideal for extending the range between cartridge exchanges. See the pictures below for examples.

Motor manufacturers who are interested in exploring the possibilities for this technology should contact us. We will be pleased to advise if a particular floorpan of any of your production vehicles may be adapted easily to use the Ecostar™ cartridge refueling system.

Contact

us:

+44 (0) 1323 831727 +44 (0) 7842 607865

Intelligent Battery Support System

The world's fastest electric circuit racers need a system to recharge batteries instantly during pit stops. The Formula E concept design above incorporates the patent Bluebird™ instant energy transfer system - allowing EV refuelling in around 10 seconds. Get your free developer License from Bluebird Marine Systems Ltd.

Lithium Polymer Suppliers and manufactures:

Kokam

Kokam possesses its own unique, proprietary technology (the Superior Lithium Polymer Battery or SLPB), which has proven marketability over existing and perceived competition. Substantial opportunities exist to tap into the market of cellular phone manufacturers and distributors who seek better lithium-ion batteries than those readily available on the market. The challenge is to bring cost-efficiency to the major channel members and OEMs, and Kokam has met this challenge. As more and more of the world's population have gained an interest in these products (as well as notebook computers and similar portable devices), the demand for lithium-ion batteries has also increased and will continue to increase over the next five years. Kokam's particular patented design employing the next generation lithium-ion/polymer technology, will increasingly occupy more and more of the total rechargeable battery sales in this industry. Based on its advanced technology and price competitiveness, Kokam's market share will be extended as fast as it is able to increase production capacity. The cellular phone industry represents very strong demand for this next generation technology, which far exceeds the overall industry's production capacity. Additionally, the size of market for notebook pc and PDA is being increased fast will be a great opportunity for Kokam. Kokam makes high standard and reliable re-chargeable Lithium battery and its processing equipments and also develop new advanced technologies for future.

http://www.kokam.com/english/biz/kokam.html

SANYO

SANYO has developed a lithium polymer battery that is ultra-thin (under 4mm) & ultra-light with superior performance, SANYO reliability, and new technology developed in our labs. Lithium polymer batteries employ a new gel-type electrolyte to provide power to the most demanding application in the hand-held world. Once again, SANYO has developed the answer to the demand for ultra-thin, ultra-light, high-power applications.

http://www.sanyo.com/batteries/lithpol.cfm

PowerStream

http://www.powerstream.com/li-pol.htm

|

||||||||

|

EDUCATION | E. CYCLES | SOLAR CARS | SOLAR CAR TEAMS | SOLARNAVIGATOR |

||||||||

|

This

website is copyright © 1991- 2014 Electrick Publications. All rights

reserved. The bird logo Max Energy Limited is an educational charity. |