|

The

tyre (or tire) was first invented and patented by R W Thomson. He patented

the Pneumatic Tyre in 1845. His first design used a number of thin

inflated tubes inside a leather cover. This design actually had its

advantages over later designs. It would take more than one puncture to

deflate the whole tyre, and varying the pressures could alter the ride

conditions.

RW

Thomson - Tyre Invention 1845

In

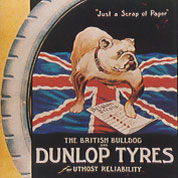

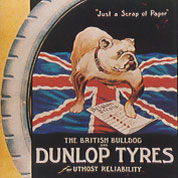

1888, Scottish-born John Boyd Dunlop, a prosperous Veterinary Surgeon in

practice in Belfast, Ireland, invented the Pneumatic Bicycle Tyre. A

group of Irish businessmen from Dublin, realised the potential of the

tyre, and, in 1889, together with Mr. Dunlop, formed a syndicate to

float what was to become "THE DUNLOP PNEUMATIC TYRE COMPANY."

The

first pneumatic bicycle tyres to reach Australia arrived in Melbourne in

1889, and within 2 years, the Dunlop Company was established in Europe

& North America ( the first pneumatic bicycle tyres to reach North

America arrived in New York on Christmas Day, 1890).

In 1893, the Dublin Company opened a Branch Office and Factory in

Melbourne, Australia, right in the heart of Melbourne's Chinatown

district.

It

was not until the late nineteenth century, 1888, that John Boyd Dunlop

invented the Rubber

Pneumatic Tyre. Despite these technological

breakthroughs the solid rubber tyre continued to be the dominant tyre

and it was not until 1889 that the pneumatic tyre caught on.

Since the bicycle was the popular form of transport, and Cycle Racing

the most popular sport, the introduction of the pneumatic tyre was an

unqualified success. In spite of this, the Dunlop Company ran into

financial difficulties and decided to sell its overseas holdings.

In

1899, a Canadian syndicate purchased the Australasian interests and

floated "THE DUNLOP PNEUMATIC TYRE COMPANY OF AUSTRALASIA LTD as an

Australian company, with a capital of 170,000 Pounds ($A 340, 000).

In

1905, the Company made the first of its many acquisitions with the

purchase of its main rival the Barnet Glass Rubber Company.

In 1889, John Boyd Dunlop founded the Pneumatic Tyre Company and

Booth's Cycle Agency, which were to become the Dunlop Rubber Company

Limited.

The company became involved in aviation in 1910, when Dunlop Rubber

Company introduced a wire-spoked wheel with a beaded tyre specifically

designed for the aviation market.

In 1925, Dunlop formed a separate Aviation Division to produce

Dunlop was a Scottish vet living in Belfast. His son Johnny

complained that when he rode his bicycle to school the cobbled streets

made his bottom sore. Dunlop solved his son's problem by inventing a

pneumatic tyre, but then it became clear that this tyre was faster - the

lad kept winning cycle races. There was a famous cycle race on the

Queen's College playing fields on 18 May 1889 and Dunlop persuaded the

cycle champion Willie Hume to use the new tyres. Willie won the race and

everybody wanted the tyres, and so the Dunlop Rubber Company was formed.

What Dunlop did not realise was that 43 years earlier another Scot

had patented almost the same thing. Robert Thomson, who had been to

America, returned to Britain and was given a workshop by his father

where he invented all sorts of things. In 1845 Thomson patented what he

called aerial wheels. There were no bicycles then, so it would not have

been a bicycle tyre that he invented. There were no internal combustion

engines either, just a few steam carriages, and otherwise horse-drawn

carriages and carts. However, Thomson did some elegant experiments.

He

fitted his tyres to a carriage and, in Regent's Park in London, had it

pulled side by side with an ordinary carriage. He showed it was much

easier to pull the one with pneumatic tyres. All the watching

journalists thought it would be slower because the tyres were soft. It

was easier to pull and also silent - it did not make the noise of a

carriage. The pneumatic tyres were a huge success but there was no

market at the time - rubber was very expensive in the 1840s.

Robert Thomson is much under-rated. He invented a whole range of

things including a fountain pen - possibly the first fountain pen,

though there are other claimants. He never became rich and famous,

perhaps because he was so far ahead of his time.

Dunlop

first advertised his tyres in December 1888 in The Irish Cyclist, and in

May of the following year the Tyre had its first breakthrough. A Belfast

Cycle Race was won on pneumatic rubber tyres, and by now the public were

starting to take note.

Unfortunately

the original tyre had its drawbacks. The inner tube was difficult to get

at because the tyre was stuck to the wheel. In 1890 CK Welsh patented

the design of a wheel rim and outer cover with inextensible lip. By now

we had the basics for today’s tyre. Over the years the tyre has

developed into today’s high technology offerings. Two of the most

important technical developments include Michelin’s

creation of the radial tyre with its vastly superior grip in 1948, and

when Dunlop did

away with the inner tube on car tyres in 1972.

RW

Thomson - Tyre Invention 1845

Time

has given the motor industry tyres capable of many different

applications. This ranges from High Speed Racing such as Formula One to

Heavy Plant Usage on vehicles as large as a house. All tyres deliver a

comfortable ride, relative puncture resistance, wear and performance.

The importance of a tyre must not be taken for granted. After all a tyre

is your vehicles only point of contact with the road.

MOST

POPULAR MAKES 2021 - A to Z

Michelin, Clermont-Ferrand, France

Apollo, Gurgaon, Haryana, India

Bridgestone, Kurume, Fukuoka,

Japan

Continental AG, Germany

Cooper, Tyre and Rubber Company, America (motorcycles)

CST Cheng Shin Rubber Ind Co Ltd (bicycle)

Hankook Tire Group, Seoul,

South

Korea

Gait, Singapore,

Inodnesia

Goodyear Tire & Rubber Company, Akron, Ohio, USA

Hankook Tire Group, Seoul, South Korean

Huayi,

Shaghai, China

Kumho Tire Co., Gwangju, South Korea

Maxis, Cheng Shin Rubber

MRF Madras Rubber Factory,

India

Nexen Tire Corporation

Nokian, Finland

Pirelli, Milan, Italy

Sumitomo Rubber Industries, Japan (Dunlop)

Toyo Tire & Rubber, Toyota, Japan

Yokohama Tire Corporation, Tokyo

THE

PLANET NEEDS OUR HELP - If we are to continue our motoring

pleasure without destroying our planet and the health of people all

over the world, we urgently need international legally binding laws

that apply to all members of the

United

Nations. Humans

created this mess, humans should clear it up.

RUBBER

& PLASTIC POLLUTION - PHYSCIS.ORG 14 NOVEMBER 2019

Where do these lost centimeters of tire tread "disappear" to as yur tyres wear out? As micro-rubbers, they mainly end up in soil and water and, to a small extent, in the air. And the amount of these particles in our environment is anything but small, as Empa researchers have now calculated.

Everybody is talking about microplastics. But the amount of microplastics in air and water is small compared to another polymer that pollutes our air and water—and therefore our organism: Micro rubber. These are the finest particles from tire abrasion, which enter our soil and air via the road surface or are removed by artificial turf. Empa researchers have now calculated that over the last 30 years, from 1988 to 2018, around 200,000 tonnes of micro rubber have accumulated in our environment in Switzerland. This is an impressive figure that has often been neglected in the discussions on microplastics.

SQUEALING TIRES

Researchers around Bernd Nowack from Empa's "Technology and Society" lab identified car and truck tires as the main source of micro-rubber. "We quantified the abrasion of tires, but also the removal of artificial green areas such as artificial turf," says Nowack. However, this only plays a subordinate role, because only three percent of the rubber particles emitted come from rubber granulate from artificial green areas. Tire abrasion is responsible for the remaining 97 percent. Of the particles released into the environment, almost three-quarters remain on the left and right side of the road in the first five meters, 5 percent in the remaining soils and almost 20 percent in water bodies. The team based its calculations on data on the import and export of tires and then modeled the behavior of rubber on roads and in road waste water. Since the year 2000, the guidelines for the recycling of water and the prevention of soil pollution have been significantly tightened. Through measures such as the construction of road wastewater treatment plants (SABA), part of the microrubber can now be removed from the water.

LOW IMPACT ON HUMANS

A part of the micro rubber is first transported by air into the first five meters left and right of the road, deposited and partly whirled up again. However, Christoph Hüglin from Empa's "Air Pollution / Environmental Technology" lab estimates the impact on humans to be low, as a study from 2009 shows. "The proportion of tire abrasion in inhaled fine dust is also in the low single-digit percentage range at locations close to traffic," says Hüglin.

Researchers emphasize, however, that microplastic and microrubber are not the same. "These are different particles that can hardly be compared with each other," says Nowack. And there are also huge differences in quantity: According to Nowack's calculations, only 7 percent of the polymer-based microparticles released into the environment are made of plastic, while 93 percent are made of tire abrasion. "The amount of microrubber in the environment is huge and therefore highly relevant," says

Nowack.

WHAT CAR 29 MAY 2019

Previous research from the USA has estimated that 30% of the microplastics that are polluting Earth's oceans and waterways comes from tyres.

Other research done in Germany in 2018 found that microplastics from tyres and vehicle brake pads made up 89% of the particles taken from the air above motorways. The scientists believe these tiny particles are being blown by the wind and washed by rain into waterways that lead to oceans.

WHAT IS THE GOVERNMENT DOING ABOUT THE PROBLEM ?

In the wake of a number of recent studies of microplastic pollution in the world’s oceans and the air above busy motorways, the UK government commissioned research into the issue in May 2018. The results from this 11-month project, conducted by Plymouth University, are due soon.

The Department for Food and Rural Affairs (DEFRA) pledged £200,000 to pay for the research, which will analyse how tiny plastic particles from tyres and other synthetic materials, such as polyester from fishing nets, ropes and lines, enter our waterways and oceans and the impact they have on marine life.

Environment minister Thérèse Coffey commented on the DEFRA-funded research: “The impact of plastic pollution on our oceans is one of the greatest environmental challenges of our generation. Robust scientific evidence should support our policy proposals, and through this exciting project, we will build on work under way to better understand how microplastics end up in marine environment and what we can do to tackle this in the future.”

WHAT ARE TYRE MANUFACTURERS DOING ABOUT THE PROBLEM ?

Tyre makers refute the claims made from previous research. Eleven of the world’s leading tyre makers formed a global forum in 2005 to look at issues relating to tyre particulates. The Tyre Industry Project (TIP) aims to proactively identify and address the potential human health and environmental impacts associated with tyres.

According to a spokeswoman from Continental Tyres, which is also a member of the TIP, the microplastics from roads consist of 50% of material from tyres and 50% of material from the actual road surface. She stated that contrary to other research, the German company's initial investigations show that only 2% of tyre microplastics have the potential to get into oceans, because they're heavier than water so sink to the bottom of rivers rather than make it to the ocean. TIP is continuing its research and expects to publish findings in 2020.

WHICH ARE THE BEST TYRE BRANDS & HOW CAN YOU SAVE MONEY ON TYRES ?

You probably don’t give your car’s tyres much thought until a garage tells you they need replacing, but they're one of the most important safety items on your car. They provide the only contact between your car and the road and ensure that it makes it around each corner and stops when you want it to.

In fact, every manoeuvre you make in your car relies on the tyres, so it’s vital to ensure they are in first-rate condition and that when you replace them, you do so wisely.

WHEN SHOULD YOU REPLACE TYRES ?

Although the legal limit for tyre tread depth is 1.6mm, many safety organisations and tyre makers recommend replacing tyres when the tread reaches 3mm, because their effectiveness – in particular their ability to stop a car on a wet surface – is reduced once the tread is below this level. They must also have the minimum tread across three-quarters of their width without any gaps.

The other legal requirements for tyres are that they are in physically good condition – they can’t have any gashes or bulges in the sidewalls – and are inflated to the recommended pressures. The tyres also have to be the same size across both axles, although you can fit larger tyres on the back or front axle of your car.

Break any of these rules and you could get three penalty points on your licence and a £2500 fine. You could lose your licence altogether and be fined £10,000 if all four tyres are below the legal limit.

Although there’s no legal requirement to stick with the brand of tyre fitted to your car when it was new, the car's maker will have worked closely with the tyre company during development, so changing to a different brand or tyre with a different tread pattern could affect the handling and road noise. However, if you stick with a similar tyre from a different premium or mid-range brand, the differences should be minimal.

One thing you should consider doing, however, is changing the two front or rear tyres at the same time, unless you’re replacing a new tyre that’s been damaged. If you change a single tyre and the new one has 8mm of tread and the one on the other side has 4mm, they won’t provide the same grip. While this isn’t likely to be an issue on dry roads, stopping distances will increase in wet and wintry conditions.

You might be able to save money by looking for retailers that offer a discount for buying more than one tyre.

SHOULD YOU FIT NEW TYRES ON THE FRONT OR BACK ?

Most modern cars are front-wheel-drive, so the front tyres have to work harder than the rears and are likely to wear out quicker. However, whether your car is front, rear or four-wheel drive, most safety experts advise switching the tyres around when replacing the front pair so that the new ones are on the rear.

This is because if a car loses grip in a corner, it will either understeer or oversteer. Understeer is when the car’s front tyres lose grip first, making the front end slide outwards. Oversteer is when the rear tyres lose grip first, making the back end of the car swing out.

It’s easier to get a car that’s understeering back under control than one that’s oversteering – simply slowing down should help to regain grip – and this is why the new tyres should be on the rear wheels to minimise the potential to oversteer and risk a serious accident.

TYRE INFLATION

PRESSURES

Although cars are

manufactured to give trouble free motoring over long distances, the

tyres should still be checked weekly. Tyres expand when they heat up,

and this happens when you start driving, so the best time to check your

tyre pressures is first thing in the morning before you leave home. If

you do check the pressures during a journey, and they read higher than

the normal recommended pressure, do not reduce the pressure. It is less

dangerous to drive with over-inflated tyres than it is to do so with

under inflated ones. However, the best solution is regular checking to

establish the correct pressure at all times.

Too much

If the front tyres on a

front wheel drive vehicle are over-inflated, the tyre becomes hard, and

the area of tyre in contact with the road is reduced. This then means

that the grip of the tyre is also reduced. In bad weather, the steering

becomes less positive, and the tyre will wear more in the centre,

because of the over-inflation. The same applies on the rear tyres of a

rear wheel drive vehicle.

Too little

As we mentioned earlier,

it is actually most dangerous to drive a car with under-inflated tyres.

The main reason for this is that under-inflation causes the tyre to

become less rigid, and consequently offers inferior control to the

steering functions, and ironically can cause less of the tyre to be in

contact with the road surface. It is equally dangerous to both front and

rear tyres to have them under-inflated. Continued use under these

circumstances increases the likelihood of the tyre casing breaking, as

the internal heat of the tyre will increase due to the lack of

sufficient air inside the tyre.

Finally, given the

increasing environmental concerns facing us all, under-inflated tyres

lead to increased fuel consumption.

On the side of your tyre,

you will see a code. This is an international code, which shows the type

of tyre and the specification. Those numbers and letters tell you

exactly about your tyre.

This is what they stand

for (from left to right):

155 - is the nominal

tyre width in millimetres.

70 - is the height as a

percentage of width, the Profile. In this case (from rim flange to

tread) it is 70% of 155mm, or 108mm.

R - means that it is a

radial tyre.

13 - is the wheel

diameter in inches.

75 - is the code for the

carrying capacity per wheel of the car. Code 75 = 387kg.

T - is the maximum speed

rating for the tyre. This tyre is rated at 118mph. The full table is

below.

Never

put two different types of tyres on the same axle. Indeed, fitting a

radial and a cross ply tyre on the same axle is illegal. It is possible

to have radials on the rear and cross ply on the front axles, but not

the other way round, and is not recommended. The only exception to this

is in the case of temporary use spare tyres.

WHAT

IS THE 'OFFSET'

One of the most asked questions, what's

the offset closely followed by what is the biggest wheel that can I fit

onto my car? The offset is a gauge of how much a wheel will stick out

from the arch of a car or how far it will recess into the arch of the

car. If the offset is wrong, the wheels will stick out too far and will

almost be a like a beach buggy!

If you take a wheel and cut it in half

and draw a line down the centre of the width of a wheel, the offset

would be the distance between the back face (mounting face) of the wheel

and the centre line that you have just drawn (shown as a dotted line in

the diagram below.

It is very

important not to deviate too far from the offset of the wheel originally

fitted to the vehicle. In this case Vauxhall engineers developed the

'Negative Scrub Geometry". This gave a offset of -49mm (et49). A

wheel of radically different offset can cause serious clearance and

handling problems along with accelerated tyre and bearing wear.

|

The

offset is commonly shown as a et number, i.e.et49. This

means the offset is 49mm. The offset is always measured in

millimetre's and can

normally be found at the back of the wheel or stamped behind the

centre cap (if fitted).

|

Negative scrub

geometry had the intention that if you got a flat tyre you were still

able to control the car (so long as you weren't going motorway speeds).

So its best to keep as close to the et49 figure as possible.

However the bigger

the alloy wheel goes, the more difficult it becomes to stay close to the

et49. The reason being is that as wheel gets bigger in diameter, it also

becomes wider, and so does the tyre that fits it. This is when other

items in the wheel arch can begin to foul with the alloy wheel or the

tyre. Namely the arch lip of the car and the suspension strut. When this

happens the offset must change for the bigger wheel and tyre to fit in

the arch. Plus if the car has been lowered, this will have to be

considered too as the wheel is now tucked further up in the arch.

Tips on keeping safe and being prepared

Changing a tyre can be a daunting prospect. Here are a few hints that

can make life easier when changing a tyre.

-

Gloves

– Keep a pair in the car at all times.

-

Bin Liner

– Something to put a muddy tyre into.

Keeps your car clean.

-

Sturdy Board

– If the ground is soft the jack

may sink. Use as a stand.

-

Wheel Nuts

– Grease threads lightly to allow

easy removal.

-

Wheel Nuts

– Make sure these are tightened

correctly.

-

Wheel Nuts

– Correct tightening will allow

easier removal next time.

-

Wheel Balancing

– Always have this done after

repair.

-

Tyre Pressure

– Never drive too far or too fast

after replacing a tyre until the pressure is checked and at the

correct level. Refer to Owners Manual.

-

Spare Tyre – Check and examine condition

regularly.

PUNCTURES

It is not always necessary to replace a tyre when punctured. In some

cases the tyre can be repaired. Here are some basic guidelines.

What can be repaired?

(In accordance with British Standards (BSAU 159))

Only certain areas of the tyre can be repaired. This is demonstrated

below by Area’T’

Repairable Area - Definition of

Area'T'

Tread repair areas

The repairable area 'T' is defined as a percentage of the tyre's nominal

section width and this is dependant on the type and size of the tyre.

Radial Ply tyres – Minor Repairs to Radial Tyres

for Cars, Vans, and

Commercial Vehicles

|

AREA

T Defined as Percentage of Nominal Section Width

|

|

CAR

|

|

Up

to and including 155mm

|

60%

|

|

Above

155mm to 200mm

|

65%

|

|

Above

200mm

|

70%

|

|

Commercial

Vehicle

|

|

Up

to and Including 225mm

|

60%

|

|

Above

225mm to 305mm

|

65%

|

|

Above

305mm

|

70%

|

|

|

Radial

Tyre Limitations: Straight Penetration Damage (After

Preparation)

|

|

Type

Of Tyre

|

Maximum

size of damage at base of injury in Area T

|

|

Car

|

6mm

|

|

Commercial

Vehicle

|

10mm

|

|

Cross Ply tyres

– Minor repairs to Cross Ply tyres

for Cars, Vans, and Commercial Vehicles

|

AREA

T Defined as Percentage of Nominal Section Width

|

|

CAR

|

|

Up

to and including 155mm

|

60%

|

|

Above

155mm to 200mm

|

65%

|

|

Above

200mm

|

70%

|

|

Commercial

Vehicle

|

|

Up

to and Including 225mm

|

60%

|

|

Above

225mm to 305mm

|

65%

|

|

Above

305mm

|

70%

|

|

|

Diagonal

(Crossply) Injury Limitations: Straight Penetration

Damage (After Preparation)

|

|

Type

Of Tyre

|

Maximum

size of damage at base of injury in Area T

|

|

Car

|

6mm

|

|

Commercial

Vehicle

|

10mm

|

|

Motorcycle & Scooter Cross Ply tyres – Minor

Repairs for Tyres Motorcycles and Scooters

|

Area

T is defined as 50% of Nominal Section width

|

|

Injury

Limitations: Straight Penetration Damage

|

|

Tyre

|

Max.

Size of Damage

|

Max.

no. of repairs

|

|

Up

to J Speed Rating

|

6mm

|

2

|

|

Above

J up to V Speed Rating

|

3mm

|

1

|

|

Above

V Speed Rating

|

-

|

0

|

|

WHEN CAN A TYRE BE REPAIRED

The

following checks are

mandatory before repairing any tyre. (General Requirements of BSAU159f.)

This ensures whether a tyre is suitable for repair.

-

Minimum Tread Depth Requirement. (Cars 1.6mm, Truck &

Motorcycle 1.0mm)

-

Run-flat

Damage

-

Contamination

-

Ageing/deterioration of the rubber

-

Bead/Liner Damage

-

Previous repairs not in accordance with BS159

If any of the above is evident it is recommended that tyre is not

suitable for repair. Do not repair it. These are only

guidelines, and not an exhaustive list. Basic principles of common sense

must be adhered to when deciding upon puncture repair.

TYRE

SIDEWALL INFORMATION - WHAT DOES IT MEAN

At first glance the lettering on the side of the tyre may look

complicated. It is not meant to be that way. The lettering explains the

exact specification of the tyre you have. In short it tells you anything

that you may need to know about your tyre.

|

Sidewall Marking

|

Explanation

|

|

205

|

Width of the tyre in millimetres

|

|

50

|

Height of the tyre sidewall as a percentage of the

width. In this case 50% of 205mm. Also know as the

aspect ratio.

|

|

R

|

Radial Construction.

|

|

15

|

The diameter of the tyre's inner rim in inches

|

|

91

|

Load Capacity of Tyre (See Load Table). In this case

its 615kg

|

|

V

|

Speed Symbol. Indicates the max. speed for the tyre

at full load. In this case 149.1mph.

|

|

E4

|

ECE type approval mark, which demonstrates the tyre

has been tested as high quality by the European

Regulatory Authorities. All Tyres sold by Black Circles

carry this mark.

|

|

SPEED

RATING

It is IMPORTANT that you check your speed rating before buying your

tyres - as choosing a lower tyre speed rating could INVALIDATE your

INSURANCE.

This is indicated by the speed symbol on the tyre sidewall, and

represents the maximum speed that this tyre can sustain at full load.

Consult your vehicle manufacturer to check which speed rating your

vehicle requires. It is of the utmost importance that you stick to the

manufacturer's guidelines.

The tyre speed rating (i.e. S) is the maximum speed for which the

tyre is rated. For example, the S rating identifies speeds up to 112

mph.

Speed ratings are based on scientific tests where the tyre is run at

speeds in 6.2 mph steps in 10 minute increments until the required speed

has been met.

You will find your speed rating on the side of your tyre at the end

of a series of numbers - as follows:

|

Speed Symbol

|

Speed

Kph

|

Speed

Mph

|

|

Car

|

|

S

|

180

|

111.8

|

|

T

|

190

|

118.1

|

|

U

|

200

|

124.3

|

|

H

|

210

|

130.5

|

|

V

|

240

|

149.1

|

|

W

|

270

|

167.8

|

|

Y

|

300

|

186.4

|

|

VR

|

210+

|

130+

|

|

ZR

|

240+

|

150+

|

|

|

|

Speed Symbol

|

Speed

Kph

|

Speed

Mph

|

|

Winter/Reinforced

|

|

Q

|

160

|

99.4

|

|

R

|

150

|

105.6

|

|

Van

|

|

N

|

140

|

87.0

|

|

P

|

150

|

93.2

|

|

Truck

|

|

J

|

100

|

62.1

|

|

K

|

110

|

68.4

|

|

L

|

120

|

74.6

|

|

M

|

130

|

80.8

|

|

|

What is a tyre load rating?

The Load capacity of a tyre determines what payload each tyre can

carry. It is vital that you check with your manufacturer what capacity

should be put on your car. Again in cases insurance can be void if you

select the incorrect tyres. The following table shows what Index

specification can carry.

|

Load index

|

Load in kg

|

|

62

|

265

|

|

63

|

272

|

|

64

|

280

|

|

65

|

290

|

|

66

|

300

|

|

67

|

307

|

|

68

|

315

|

|

69

|

325

|

|

70

|

335

|

|

71

|

345

|

|

72

|

355

|

|

73

|

365

|

|

74

|

375

|

|

75

|

387

|

|

76

|

400

|

|

77

|

412

|

|

78

|

425

|

|

79

|

437

|

|

80

|

450

|

|

81

|

462

|

|

82

|

475

|

|

83

|

487

|

|

|

|

Load index

|

Load in kg

|

|

84

|

500

|

|

85

|

515

|

|

86

|

530

|

|

87

|

545

|

|

88

|

560

|

|

89

|

580

|

|

90

|

600

|

|

91

|

615

|

|

92

|

630

|

|

93

|

650

|

|

94

|

670

|

|

95

|

690

|

|

96

|

710

|

|

97

|

730

|

|

98

|

750

|

|

99

|

775

|

|

100

|

800

|

|

101

|

825

|

|

102

|

850

|

|

103

|

875

|

|

104

|

900

|

|

105

|

925

|

|

|

|

Load index

|

Load in kg

|

|

106

|

950

|

|

107

|

975

|

|

108

|

1000

|

|

109

|

1030

|

|

110

|

1060

|

|

111

|

1090

|

|

112

|

1120

|

|

113

|

1150

|

|

114

|

1180

|

|

115

|

1215

|

|

116

|

1250

|

|

117

|

1285

|

|

118

|

1320

|

|

119

|

1360

|

|

120

|

1400

|

|

121

|

1450

|

|

122

|

1500

|

|

123

|

1550

|

|

124

|

1600

|

|

125

|

1650

|

|

126

|

1700

|

|

|

How do I know if my tyres are Trading Standards approved?

Check your tyre for an "E" Number. E.g. E4 0213760. This is

an ECE type approval mark and number that shows if the tyre has been

tested and passed as high quality by the European regulatory

authorities.

|

Speed Rating

|

Miles/Hour

|

Kilometers/Hour

|

|

N

|

87

|

140

|

|

P

|

93

|

150

|

|

Q

|

99

|

160

|

|

R

|

106

|

170

|

|

S

|

112

|

180

|

|

T

|

118

|

190

|

|

|

Speed Rating

|

Miles/Hour

|

Kilometers/Hour

|

|

U

|

124

|

200

|

|

H

|

130

|

210

|

|

V

|

149

|

240

|

|

Z

|

150+

|

240+

|

|

W

|

168

|

270

|

|

Y

|

186

|

300

|

|

|

AIRCRAFT

TYRES

The very earliest of

tyre designs were called Type I and were referred to only by their

outside diameter eg 27" which is a common fitment to aircraft such

as Harvards or P51 Mustangs.

General Aviation tyres

are generally Type III designs and include the most widely used sizes

such as 5.00-5 and 6.00-6. These measurements refer to the section width

of a tyre and also the rim ledge diameter (or the hole in the middle)

hence a 6.00-6 is 6 inches wide and sits on 6 inch wheel.

Three Part Name Sizes

cover most of today’s designs and typically describe the Outside

Diameter, Section Width and Rim Ledge Diameter. Eg, 15x6.00-6, the tyre

is 15 inches tall, 6 inches wide and sits on a 6 inch wheel. Some tyres

in this classification are preceded with an ‘H’ which identifies the

tyre as having a higher percentage deflection.

Metric sizes are the

same as three part name sizes but the Overall Diameter and Section Width

are replaced with millimeters but the rim sizes remains in inches, eg

380x150-5, it’s imperial equivalent is a 15x6.00-5.

Radial tyres are also

the same as three part name sizes but the dash preceding the rim

diameter is replaced with the letter ‘R’ eg 32x8.8R16

|

Type

|

Tyre

Size

|

Overall

Diameter

|

Section

Width

|

Wheel

Diameter

|

|

Type

1

|

27"

|

27"

|

-

|

-

|

|

Type

III

|

6.00-6

|

-

|

6.00

|

6"

|

|

Type

VII

|

40

x 14

|

40

|

14

|

-

|

|

Three

Part Name

|

19.5

x 6.75-8

|

19.5

|

6.75

|

8"

|

|

Metric

|

380

x 150-5

|

380mm

|

150mm

|

5"

|

RUN

FLAT TECHNOLOGY

Run

Flat Tyres Explained

Several Tyre Manufacturers have developed tyres, and tyre systems that

allow a vehicle to continue moving despite a loss of pressure. There are

two different approaches:

1.Reinforced Tyre Sidewall manufacturers of

this include Bridgestone, Dunlop, Goodyear

and Pirelli.

2.Rubber clip to your rim manufacturers of this include Michelin. All

Run flat technology must operate in tandem with tyre pressure warning

systems.

1.Reinforced Tyre Sidewall

The Diagram below shows The Dunlop

DSST system for run flat. These tyres can be placed on any rim. The

sidewall is reinforced allowing the tyre to support the vehicles weight.

The tyre is constructed with new rubber compounds that prevent tyre

destruction with excessive flexing. Run Flat Tyres allow a vehicle with

complete loss of tyre pressure to handle effectively. Braking,

acceleration, and steering behaviour remain unchanged. Mobility is

maintained even after a puncture, but you must refer to each individual

tyre’s guidelines from the Manufacturer.

Dunlop DSST Tyre

Tyres that carry this technology include the Bridgestone RFT series,

Dunlop DSST series, Goodyear EMT series, and the Pirelli Euphori @

series.

2. Rubber Clip to your tyre rim

The rubber clip prevents the tyre rim cutting into your tyre when you

experience a loss of pressure. This system has been developed by

Michelin and is known as the PAX System. Like the reinforced sidewall it

operates in tandem with automated tyre pressure monitors.

WHY

DO SOME PEOPLE USE NITROGEN instead of AIR ?

Why would you want to do this? The benefits of Nitrogen filling

are as follows:

-

Improved comfort of ride

-

Improved safety

-

Increased fuel savings

-

Improved life of tyre

Nitrogen has long been the accepted gas medium for filling aircraft

tyres, racing tyres and heavy mining and construction vehicle tyres.

Nitrogen is used for safety reasons and to ensure that tyres are always

at a constant pressure. Compressed air, the traditional medium for

inflating car tyres, contains both oxygen (21%) and nitrogen (78%).

The rubber tyre is like a membrane, through which oxygen permeates three

times faster than the nitrogen. The result is that the oxygen slowly

leaks out through the rubber walls, and the under-inflation leads to

higher tyre wear with a consequent decrease in safety and comfort, and

higher fuel costs.

MORE

ON WHEELS and TYRES

Fitting new wheels to your car can

affect your car more than you think. If you have

fitted a bigger wheel this will affect: Its

gearing, Speedo will not read properly, and

acceleration can be lost. To solve the problems

you can choose low-profile tyres to go with the

larger diameter wheels. So if you go up one rim

size you need to decrease the profile size by

one. This means that you can potentially put any

sized wheels on your car just as long as you can

get tyres with low enough profiles.

PCD = Pitch Circle Diameter - In English: The

number of bolts holding each wheel to its hub.

So 5x120 means that the car has 5 mounting holes

in a 120mm diameter circle.

What does the marks on the sidewalls

really mean?

Marks could be: 205/45x17 R 80V

205 = the width of the tyre in mm

45 = Sidewall height in relation to the tyre

width shown as a %. So the height is 45% of 205,

answer in mm.

R = Radial.

17 = Wheel diameter in inches.

80 = Load index in lbs.

V = Speed rating.

Tyres also have maximum speed ratings:

H

up to 130mph

T

up to 118mph

V

inside tyre size markings

(225/50 VR 16) over 130mph

V

outside tyre size markings

(185/55 R 15 v) up to 150mph

W

up to 168mph

Y

up to 186mph

Z

inside tyre size markings

(225/40 ZR 17) over 150 mph

LIST

OF POPULAR WHEELS and TYRES:

|

MODEL

|

PCD

|

OFFSET

|

RIM

STD

|

TYRE

|

RIM

WIDE

|

WHEEL & TYRE

|

|

|

|

|

|

|

|

|

|

156

|

5X98

|

45

|

7.5x17

|

225/45x17

|

8x18

|

225/40x18

|

|

|

|

|

|

|

|

|

|

A3

|

5X100

|

38

|

8x18

|

225/40x18

|

9x18

|

215/35x18

|

|

A4

|

5X112

|

38

|

8x18

|

225/40x18

|

9x18

|

215/35x18

|

|

TT

|

5X100

|

31

|

8x18

|

225/40x18

|

9x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

E30

|

4X100

|

35

|

7.5x17

|

215/40x17

|

7.5x18

|

215/35x18

|

|

E30 M3

|

5X120

|

27

|

8x17

|

215/40x17

|

8x18

|

215/35x18

|

|

E36 4 DOOR

|

5X120

|

42

|

8.5x18

|

225/40x18

|

8x19

|

235/35x19

|

|

E36 COUPE

|

5X120

|

42

|

8.5x18

|

225/40x18

|

8x19

|

235/35x19

|

|

|

|

|

|

|

|

|

|

CHARADE Gtti

|

4X100

|

14

|

6.5x15

|

195/45x15

|

7x17

|

205/40x17

|

|

|

|

|

|

|

|

|

|

CINQUECENTO

|

4X98

|

36

|

5.5x13

|

|

6x14

|

185/50x14

|

|

SEICENTO

|

4X98

|

36

|

5.5x13

|

|

6x14

|

185/60x14

|

|

UNO

|

4X98

|

45

|

6.5x15

|

195/45x15

|

6x16

|

195/45x16

|

|

PUNTO

|

4X98

|

40

|

7x15

|

195/45x15

|

7x17

|

205/40x17

|

|

BRAVO

|

4X98

|

43

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

COUPE

|

4X98

|

40

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

KA

|

4X108

|

41

|

7x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

FIESTA MK2

|

4X108

|

41

|

6x14

|

185/55x14

|

7x15

|

195/45x15

|

|

FIESTAMK3

|

4X108

|

41

|

7x15

|

195/45x15

|

7x17

|

205/40x17

|

|

PUMA

|

4X108

|

36

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

ESCORT MK3/4

|

4X108

|

36

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

ESCORT MK5/6

|

4X108

|

36-41

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

ESCORT COSWORTH

|

4X108

|

25

|

8.5x16

|

225/40x16

|

8x19

|

215/35x19

|

|

FOCUS

|

4X108

|

52

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

SIERRA/SAPHIRE

|

4X108

|

40

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

MONDEO

|

4X108

|

40-49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

PROBE

|

5X114.3

|

40

|

8x18

|

225/40x18

|

8x19

|

215/35x19

|

|

|

|

|

|

|

|

|

|

CIVIC(91-95)

|

4X100

|

45

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

CIVIC (95-ON)

|

4X100

|

45

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

CRXC (93-ON)

|

4X100

|

45

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

INTEGRA R

|

5X114.3

|

45

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

ACCORD R

|

5X114.3

|

55

|

7.5x17

|

215/45x17

|

7x18

|

215/35x18

|

|

PRELUDE (92-97)

|

4X114.3

|

50

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

COUPE (96-ON)

|

4X114.3

|

45

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

DELTA

|

4X98

|

42

|

6.5x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

|

|

|

|

|

|

|

|

323 (80-89)

|

4X114.3

|

45

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

323 (89-94)

|

4X100

|

45

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

MX3

|

4X100

|

45

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

MX5

|

4X100

|

35

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

MX6

|

5X114.3

|

42

|

8x17

|

215/45x17

|

8x18

|

225/40x18

|

|

RX-7

|

5X114.3

|

50

|

8x18

|

225/40x18

|

8.5x19

|

235x35x19

|

|

|

|

|

|

|

|

|

|

FTO

|

|

|

7.5x17

|

205/45x17

|

7.5x18

|

215/35x18

|

|

LANCER EVO I-III

|

5X114.3

|

45-46

|

7.5x17

|

215/40x17

|

7.5x18

|

215/35x18

|

|

LANCER

EVOIV-VI

|

5X114.3

|

45-46

|

8x18

|

225/40x18

|

8x19

|

215/35x18

|

|

|

|

|

|

|

|

|

|

SUNNY

GTI-R

|

4X114.3

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

ALMERA GT

|

4X100

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

PRIMERA

|

4X114.3

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

200SX (-95)

|

4X114.3

|

45

|

7x17

|

215/40x17

|

7.5x18

|

215/35x18

|

|

200SX (95-ON)

|

4X114.3

|

40

|

7.5x17

|

215/40x17

|

7.5x18

|

215/35x18

|

|

300ZX (FRONT)

|

4X114.3

|

23

|

8x18

|

225/40x18

|

8.5x19

|

235/35x19

|

|

300ZX (REAR)

|

4X114.3

|

23

|

9x18

|

255/35x18

|

10x19

|

265/30x19

|

|

|

|

|

|

|

|

|

|

106 std arch (-97)

|

3X98

|

20

|

6.5x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

106 std arch (97-)

|

3X98

|

20

|

6.5x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

106 wide arch (-97)

|

4X108

|

16

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

106 wide arch (97-)

|

4X108

|

16

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

205

|

4X108

|

19-28

|

6.5x15

|

195/45x15

|

6x16

|

195/45x16

|

|

205 GTI

|

4X108

|

19-28

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

206

|

4X108

|

34

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

309

|

4X108

|

19

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

306

|

4X108

|

19

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

405

|

4X108

|

25-29

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

406

|

4X108

|

19

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

5 GT TURBO

|

4X100

|

36

|

7x15

|

195/45x15

|

7x17

|

205/40x17

|

|

CLIO

|

4X100

|

42

|

6.5x15

|

195/45x15

|

7x16

|

195/45x16

|

|

CLIO 16V

|

4X100

|

42

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

19

|

4X100

|

42

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

MEGANE

|

4X100

|

36

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

21

|

4X100

|

36

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

21 (5 STUD)

|

5X108

|

52

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

LAGUNA

|

4X100

|

50

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

LAGUNA (5 STUD)

|

5X108

|

50

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

200 (89-95)

|

4X100

|

40

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

200 (95-00)

|

4X100

|

40

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

600

|

4X114.3

|

50

|

7x17

|

205/45x17

|

7.5x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

IBIZA (93-)

|

4X100

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

CORDOBA (94-)

|

4X100

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

IMPREZA

|

5X100

|

55

|

7x17

|

205/45x17

|

7x18

|

215/35x18

|

|

LEGACY

|

5X100

|

55

|

7x17

|

205/45x17

|

7x18

|

215/35x18

|

|

|

|

|

|

|

|

|

|

SWIFT

|

4X114.3

|

45

|

6.5x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

|

|

|

|

|

|

|

|

COROLLA (83-92)

|

4X100

|

39

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

COROLLA (92-97

|

4X100

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

COROLLA (97-ON)

|

4X100

|

45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

MR2 MK1

|

4X100

|

45

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

MR2 MK2 early

|

5X114.3

|

37

|

8x17

|

215/40x17

|

8x18

|

225/35x18

|

|

CELICA (09-94)

|

5X100

|

39-45

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

CELICA (94-00)

|

5X100

|

39-45

|

7x17

|

215/40x17

|

8x18

|

225/35x18

|

|

SUPRA (86-93)

|

5X114.3

|

37

|

8x18

|

225/40x18

|

8x19

|

215/35x19

|

|

SUPRA (93-FRONT)

|

5X114.3

|

50

|

8x18

|

235/40x18

|

8.5x19

|

235/35x19

|

|

SUPRA (93-REAR)

|

5X114.3

|

50

|

9x18

|

265/35x18

|

10x19

|

265/30x19

|

|

|

|

|

|

|

|

|

|

NOVA

|

4X100

|

49

|

6.5x16

|

195/45x16

|

7x17

|

205/40x17

|

|

CORSA

|

4X100

|

49

|

7x17

|

205/40x17

|

7x18

|

215/35x18

|

|

TIGRA

|

4X100

|

49

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

ASTRA MK2

|

4X100

|

49

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

ASTRAMK3

|

4X100

|

49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

ASTRAM MK4

|

4X100

|

49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

ASTRA MK4 Sri

|

5X110

|

49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

CAVALIER MK3

|

4X100

|

49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

CAVALIER TURBO IV

|

65X110

|

49

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

VECTRA

|

5X110

|

49

|

7x17

|

205/45x17

|

7.5x18

|

215/35x18

|

|

CALIBRA

|

4X100

|

49

|

7x17

|

205/40x17

|

8x19

|

215/35x19

|

|

CALIBRA TURBO/V6

|

5X110

|

49

|

7x17

|

205/40x17

|

8x19

|

215/35x19

|

|

|

|

|

|

|

|

|

|

POLO MK3

|

4X100

|

38

|

6.5x15

|

195/45x15

|

6.5x16

|

195/45x16

|

|

POLO MK4

|

4X100

|

38

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

GOLF MK1

|

4X100

|

38

|

7x16

|

195/45x16

|

7x17

|

205/40x17

|

|

GOLF MK2

|

4X100

|

38

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

GOLF RALLYE

|

4X100

|

38

|

7.5x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

GOLF MK3

|

5X100

|

38

|

7.5x17

|

205/40x17

|

7.5x18

|

215/35x19

|

|

GOLF MK4

|

5X100

|

38

|

8x18

|

225/40x18

|

8x19

|

215/35x19

|

|

JETTA (86-92)

|

4X100

|

38

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

BORA

|

5X100

|

38

|

8x18

|

225/40x18

|

8x19

|

215/35x19

|

|

CORRADO

|

4X100

|

38

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

|

CORRADO VR6

|

5X100

|

43

|

7x17

|

205/40x17

|

7.5x18

|

215/35x18

|

TYRE

POLLUTION LINKS

https://www.rte.ie/lifestyle/motors/2020/0918/1166000-tyre-pollution-up-to-1-000-times-worse-than-engines-study-finds/

https://airqualitynews.com/2020/03/09/air-pollution-from-tyres-1000-worse-than-from-exhaust-claims-study/

https://www.emissionsanalytics.com/news/2020/1/28/tyres-not-tailpipe

https://www.nationalgeographic.co.uk/environment-and-conservation/2019/09/tyres-plastic-polluter-you-never-thought-about

https://www.whatcar.com/advice/owning/tyres-and-microplastic-pollution-whats-the-problem-and-whats-being-done-to-address-it/n19483

https://phys.org/news/2019-11-rubber-environment.html

https://www.rte.ie/lifestyle/motors/2020/0918/1166000-tyre-pollution-up-to-1-000-times-worse-than-engines-study-finds/

https://airqualitynews.com/2020/03/09/air-pollution-from-tyres-1000-worse-than-from-exhaust-claims-study/

https://www.emissionsanalytics.com/news/2020/1/28/tyres-not-tailpipe

https://www.nationalgeographic.co.uk/environment-and-conservation/2019/09/tyres-plastic-polluter-you-never-thought-about

https://www.whatcar.com/advice/owning/tyres-and-microplastic-pollution-whats-the-problem-and-whats-being-done-to-address-it/n19483

https://phys.org/news/2019-11-rubber-environment.html

Please

click on the links above to find out about these famous automotive makers.

If your company is not included and you would like to be listed, please

let us know.

Possibly,

the

world's fastest electric car: 350mph + using energy from nature. Featuring

built in battery cartridge exchange, charged using renewable solar energy.

|