|

RUDOLF DIESEL

AUTOMOTIVE A TO Z CHARITY CONTACT EVENTS HOME SITE INDEX

|

||||||||||||||||||||||

|

Rudolf Christian Karl Diesel (March 18, 1858 – September 30, 1913) was a German inventor, famous for the invention of the Diesel engine. He was born in Paris and died on the English Channel.

Rudolf Diesel

Early life

Although Diesel was born in Paris, his parents were German. His father was a leather craftsman, and his mother a governess and language tutor. Rudolf was a good student in primary school and was admitted at the age of 12 to the Ecole Primaire Superieure, then regarded as the best in Paris. On the outbreak of the Franco-Prussian War, however, he and his parents were considered enemy aliens, and were deported to neutral asylum in London. A cousin helped him to return to his father's home town, Augsburg, where he entered the Royal County Trade School. From there he won a scholarship to the Technische Hochschule of Munich, where he was an outstanding student. He became a protegé of Carl von Linde, the pioneer of refrigeration. He was a devout Lutheran.

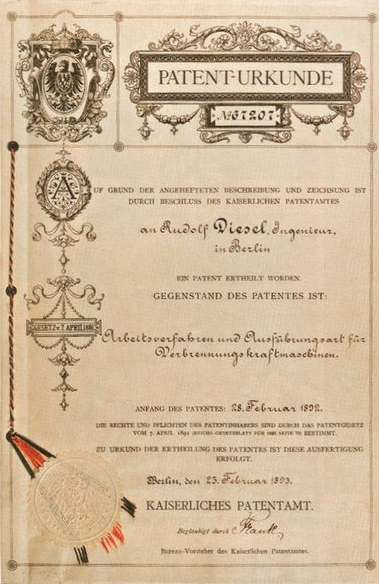

After graduation, he was employed for two years as a machinist and designer in Winterthur, Switzerland. After this, he returned to Paris, where he was employed as a refrigeration engineer at Linde Refrigeration Enterprises. In Paris he became a connoisseur of the fine arts and an internationalist. He married in 1883, and had three children. He set up his first shop-laboratory in 1885 in Paris, and began full-time work on his engine. This continued when he moved to Berlin, working again for Linde Enterprises. In 1892 he was granted a German patent for the engine, and found some support for its continued development, this time in Augsburg.

The invention

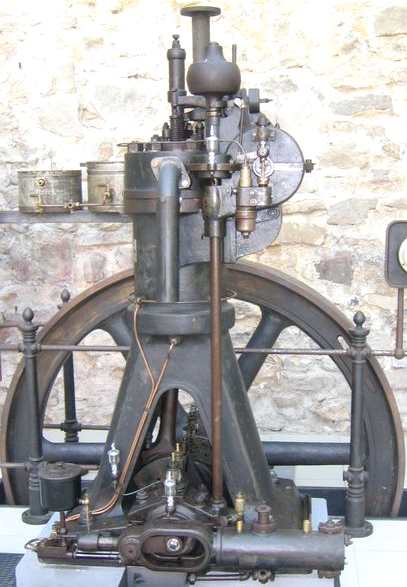

Rudolf Diesel developed the idea of an engine that relied on a high compression of the fuel to ignite it, eliminating the spark plug used in the Nikolaus Otto internal combustion engine. He received a patent for the device on February 23, 1892. Diesel began building a prototype engine, which was ready for testing by July 1893. The engine was fueled by powdered coal injected with compressed air. This machine stood 10 feet (3 m) tall, and achieved a compression of 80 atmospheres (8100 kPa). It exploded and nearly killed Diesel. Nevertheless, about seven months later a major milestone was achieved when he was able to run a single piston engine for one minute on February 17, 1894. This engine only generated 13 horsepower. He built an improved prototype in early 1897 while working at the Maschinenfabrik Augsburg (from 1906 on the MAN) plant at Augsburg. Diesel's engine had some similarities with an engine invented by Herbert Akroyd Stuart in 1890. Diesel was embroiled for some years in various patent disputes and arguments over priority, but in the end he prevailed, and his invention came to be called the diesel engine. He continued its development over the next three years, began production (the first commercial engine was at a brewery in the United States), and secured licenses from firms in several countries. He became a millionaire.

Rudolf Diesel's patent 1893

DIESEL FUEL OIL

Diesel or diesel fuel is a specific fractional distillate of fuel oil (mostly petroleum) that is used as fuel in a diesel engine invented by German engineer Rudolf Diesel. The term typically refers to fuel that has been processed from petroleum, but increasingly, alternatives such as biodiesel or biomass to liquid (BTL) or gas to liquid (GTL) diesel that are not derived from petroleum are being developed and adopted.

Petroleum diesel

Diesel is produced from petroleum, and is sometimes called petrodiesel (or, less seriously, dinodiesel) when there is a need to distinguish it from diesel obtained from other sources such as vegidiesel (biodiesel) derived from pure (SVO) or recycled waste (WVO) vegetable oil. As a hydrocarbon mixture, it is obtained in the fractional distillation of crude oil between 250 °C and 350 °C at atmospheric pressure.

The density of diesel is about 850 grams per liter whereas petrol has a density of about 720 g/l, about 15% less. When burnt, diesel typically releases about 40.9 megajoules (MJ) per liter, whereas petrol releases 34.8 MJ/L, also about 15% less. Diesel is generally simpler to refine than petrol and often costs less (although price fluctuations sometimes mean that the inverse is true; for example, the cost of diesel traditionally rises during colder months as demand for heating oil, which is refined much the same way, rises).

Diesel powered cars generally have greater fuel economy than gasoline powered cars, which is due to the greater energy content of diesel fuel and also the intrinsic efficiency of the diesel engine. That translates commonly in a 40% better milage than equivalent gasoline engines. Proponents of diesel powered automobiles often cite this advantage as a way to reduce Greenhouse gas emissions. However, diesel's 15% higher volumetric energy density results in 15% higher greenhouse gas emissions per liter compared to gasoline, it's the 40% better fuel economy that the modern diesel's car have that offsets the emissions of greenhouse gases, resulting in less CO2 emission per mile.

Also, diesel fuel often contains higher quantities of sulfur. European emission standards and preferential taxation have forced oil refineries to dramatically reduce the level of sulfur in diesel fuels. In contrast, the United States has long had "dirtier" diesel, although more stringent emission standards have been adopted with the transition to ultra-low sulfur diesel (ULSD) starting in 2006 and becoming mandatory on June 1, 2010 (see also diesel exhaust). U.S. diesel fuel typically also has a lower cetane number (a measure of ignition quality) than European diesel, resulting in worse cold weather performance and some increase in emissions. High levels of sulfur in diesel are harmful for the environment. It prevents the use of catalytic diesel particulate filters to control diesel particulate emissions, as well as more advanced technologies, such as nitrogen oxide (NOx) adsorbers (still under development), to reduce emissions. However, lowering sulfur also reduces the lubricity of the fuel, meaning that additives must be put into the fuel to help lubricate engines. Biodiesel is an effective lubricant.

Chemical composition

Petroleum derived diesel is composed of about 75% saturated hydrocarbons (primarily paraffins including n, iso, and cycloparaffins), and 25% aromatic hydrocarbons (including naphthalenes and alkylbenzenes). The average chemical formula for common diesel fuel is C12H26, ranging from approx. C10H22 to C15H32.

Algae, microbes, and water

There has been a lot of discussion and misinformation about algae in diesel fuel. An alga is a plant, and it requires sunlight to live and grow. As there is no sunlight in a closed fuel tank, no algae can survive there. However, some microbes can survive there. They can feed on the diesel fuel.

These microbes form a slimy colony that lives at the fuel/water interface. They grow quite rapidly in warmer temperatures. They can even grow in cold weather when fuel tank heaters are installed. Parts of the colony can break off and clog the fuel lines and fuel filters.

It is possible to either kill this growth with a biocide treatment, or eliminate the water, a necessary component of microbial life. There are a number of biocides on the market, which must be handled very carefully. If a biocide is used, it must be added every time a tank is refilled until the problem is fully resolved.

Biocides attack the cell wall of microbes resulting in lysis, the death of a cell by bursting. The risk of filter clogging may continue for a short period after biocide treatment until cellular residues break down and are absorbed into the fuel.

Synthetic diesel

Wood, straw, corn, garbage, and sewage-sludge may be dried and gasified. After purification the Fischer Tropsch process is used to produce synthetic diesel. Other attempts use enzymatic processes and are also economic in case of high oil prices. Synthetic diesel may also be produced out of natural gas in the GTL process or out of coal in the CTL process. Such synthetic diesel has 30% less particulate emissions than conventional diesel (US- California).

1906 single cylinder diesel engine

Biodiesel

Biodiesel can be obtained from vegetable oil (vegidiesel / vegifuel), or animal fats (bio-lipids, using transesterification). Biodiesel is a non-fossil fuel alternative to petrodiesel. It can also be mixed with petrodiesel in any amount in modern engines, though when first using it, the solvent properties of the fuel tend to dissolve accumulated deposits and can clog fuel filters. Biodiesel has a higher gel point than petrodiesel, but is comparable to diesel #2. This can be overcome by using a biodiesel/petrodiesel blend, or by installing a fuel heater, but this is only necessary during the colder months. There have been reports that a diesel-biodiesel mix results in lower emissions than either can achieve alone. A small percentage of biodiesel can be used as an additive in low-sulfur formulations of diesel to increase the lubricity lost when the sulfur is removed.

Chemically, most biodiesel consists of alkyl (usually methyl) esters instead of the alkanes and aromatic hydrocarbons of petroleum derived diesel. However, biodiesel has combustion properties very similar to petrodiesel, including combustion energy and cetane ratings. Paraffin biodiesel also exists. Due to the purity of the source, it has a higher quality than petrodiesel.

Ethanol can be added to petroleum diesel fuel in amounts up to 15% along with additives to keep the ethanol emulsified. APPLICATIONSInternal Combustion Engines

Diesel oil is used in diesel engines, a type of internal combustion engine. Rudolf Diesel originally designed the diesel engine to use peanut oil as a fuel in order to help support agrarian society. Diesel engines are used in cars, trucks, motorcycles, boats and locomotives.

Packard diesel motors were used in aircraft as early as 1927, and Charles Lindbergh flew a Stinson SM1B with a Packard Diesel in 1928. A Packard diesel motor designed by L.M. Woolson was fitted to a Stinson X7654, and in 1929 it was flown 1000 km non-stop from Detroit to Langley, Virginia (near Washington, D.C.). In 1931, Walter Lees and Fredrick Brossy set the nonstop flight record flying a Bellanca powered by a Packard Diesel for 84h 32m. The Hindenburg was powered by four 16 cylinder diesel engines, each with approximately 1200 horsepower available in bursts, and 850 horsepower available for cruising.

The very first diesel-engine automobile trip was completed on January 6, 1930. The trip was from Indianapolis to New York City, a distance of nearly 800 miles (1300 km). This feat helped to prove the usefulness of the internal combustion engine. More specifically, diesel engines are a compression ignition engine, in which the fuel is ignited by being suddenly exposed to the high temperature and pressure of a compressed gas, rather than by a separate source of ignition, such as a spark plug, as is the case in the gasoline engine. This is known as the diesel cycle, after German engineer Rudolf Diesel, who invented it in 1892 based on the hot bulb engine and received the patent on February 23, 1893. Diesel intended the engine to use a variety of fuels including coal dust. He demonstrated it in the 1900 Exposition Universelle (World's Fair) using peanut oil (see biodiesel).

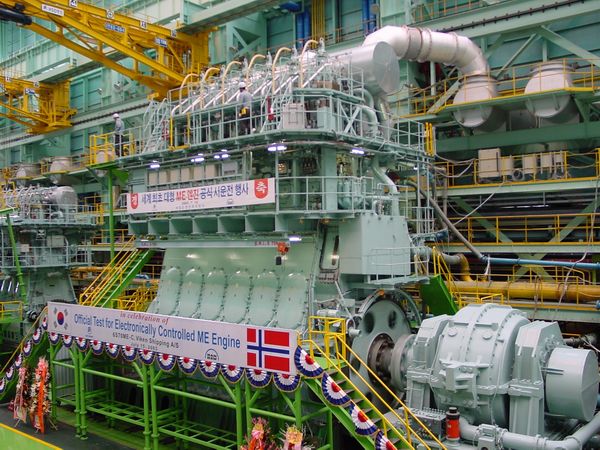

The modern diesel engine is a combination of two inventor's creations. In all major aspects, it holds true to Diesel's original design, of the fuel being ignited by compression. However, nearly all present-day diesel engines use the so-called 'cold-fuel' injection system invented by Herbert Akroyd Stuart, inventor of the hot bulb engine (a compression-ignition engine that precedes the diesel engine and operates slightly differently).'Cold-Fuel' injection is where the fuel is raised to extreme pressures by mechanical pumps and delivered to the combustion chamber by pressure-activated injectors. Diesel's original engine injected fuel with the assistance of compressed air, which atomised the fuel and forced it into the engine through a nozzle. The compressed air heated the fuel slightly, hence the name 'hot-fuel' injection. Cold-fuel systems are lighter, simpler and allow much faster engine speeds, and so are universally used for automotive diesel engines. Hot-fuel systems provide very efficient combustion under low-speed, high-load conditions, especially when running on poor-quality fuels, and so some large 'cathedral' marine engines use hot-fuel injection.

JCB diesel engine

How diesel engines work

When a gas is compressed, its temperature rises (see the combined gas law); a diesel engine uses this property to ignite the fuel. Air is drawn into the cylinder of a diesel engine and compressed by the rising piston at a much higher compression ratio than for a spark-ignition engine, up to 25:1. The air temperature reaches 700–900 °C, or 1300–1650 °F. At the top of the piston stroke, diesel fuel is injected into the combustion chamber at high pressure, through an atomising nozzle, mixing with the hot, high-pressure air. The resulting mixture ignites and burns very rapidly. This contained combustion causes the gas in the chamber to heat up rapidly, which increases its pressure, which in turn forces the piston downwards. The connecting rod transmits this motion to the crankshaft, which is forced to turn, delivering rotary power at the output end of the crankshaft. Scavenging (pushing the exhausted gas-charge out of the cylinder, and drawing in a fresh draught of air) of the engine is done either by ports or valves. To fully realize the capabilities of a diesel engine, use of a turbocharger to compress the intake air is necessary; use of an aftercooler/intercooler to cool the intake air after compression by the turbocharger further increases efficiency.

In very cold weather, diesel fuel thickens and increases in viscosity and forms wax crystals or a gel. This can make it difficult for the fuel injector to get fuel into the cylinder in an effective manner, making cold weather starts difficult at times, though recent advances in diesel fuel technology have made these difficulties rare. A commonly applied advance is to electrically heat the fuel filter and fuel lines. Other engines utilize small electric heaters called glow plugs inside the cylinder to warm the cylinders prior to starting. A small number use resistive grid heaters in the intake manifold to warm the inlet air until the engine reaches operating temperature. Engine block heaters (electric resistive heaters in the engine block) plugged into the utility grid are often used when an engine is shut down for extended periods (more than an hour) in cold weather to reduce startup time and engine wear.

A vital component of older diesel engine systems was the governor, which limited the speed of the engine by controlling the rate of fuel delivery. Unlike a petrol (gasoline) engine, the incoming air is not throttled, so the engine would overspeed if this was not done. Older injection systems were driven by a gear system from the engine (and thus supplied fuel only linearly with engine speed). Modern electronically-controlled engines apply similar control to petrol engines and limit the maximum RPM through the electronic control module (ECM) or electronic control unit (ECU) - the engine-mounted "computer". The ECM/ECU receives an engine speed signal from a sensor and then using its algorithms and look-up calibration tables stored in the ECM/ECU, it controls the amount of fuel and its timing (the "start of injection") through electric or hydraulic actuators to maintain engine speed.

Controlling the timing of the start of injection of fuel into the cylinder is key to minimising the emissions, and maximising the fuel economy (efficiency), of the engine. The exact timing of starting this fuel injection into the cylinder is controlled electronically in most of today's modern engines. The timing is usually measured in units of crank angle of the piston before Top Dead Center (TDC). For example, if the ECM/ECU initiates fuel injection when the piston is 10 degrees before TDC, the start of injection or "timing" is said to be 10 deg BTDC. The optimal timing will depend on both the engine design as well as its speed and load.

Advancing (injecting when the piston is further away from TDC) the start of injection results in higher in-cylinder pressure, temperature, and higher efficiency but also results in higher emissions of Oxides of Nitrogen (NOx) due to the higher temperatures. At the other extreme, very retarded start of injection or timing causes incomplete combustion. This results in higher Particulate Matter (PM) and unburned hydrocarbon (HC) emissions and more smoke.

Fuel injection in diesel engines

Mechanical and electronic injection

Older engines make use of a mechanical fuel pump and valve assembly which is driven by the engine crankshaft, usually from the timing belt or chain. These engines use simple injectors which are basically very precise spring-loaded valves which will open and close at a specific fuel pressure. The pump assembly consists of a pump which pressurizes the fuel, and a disc-shaped valve which rotates at half crankshaft speed. The valve has a single aperture to the pressurized fuel on one side, and one aperture for each injector on the other. As the engine turns the valve discs will line up and deliver a burst of pressurized fuel to the injector at the cylinder about to enter its power stroke. The injector valve is forced open by the fuel pressure and the diesel is injected until the valve rotates out of alignment and the fuel pressure to that injector is cut off. Engine speed is controlled by a third disc, which rotates only a few degrees and is controlled by the throttle lever. This disc alters the width of the aperture through which the fuel passes, and therefore how long the injectors are held open before the fuel supply is cut, controlling the amount of fuel injected.

Older diesel engines with mechanical injection pumps could be inadvertently run in reverse, albeit very inefficiently as witnessed by massive amounts of soot being ejected from the air intake. This was often a consequence of Bump starting a vehicle using the wrong gear.

This contrasts with the more modern method of having a separate fuel pump (or set of pumps) which supplies fuel constantly at high pressure to each injector. Each injector then has a solenoid which is operated by an electronic control unit, which enables more accurate control of injector opening times depending on other control conditions such as engine speed and loading, resulting in better engine performance and fuel economy. This design is also mechanically simpler than the combined pump and valve design, making it generally more reliable, and less noisy, than its mechanical counterpart.

Both mechanical and electronic injection systems can be used in either direct or indirect injection configurations. (see below)

Indirect injection

An indirect injection diesel engine delivers fuel into a chamber off the combustion chamber, called a prechamber, where combustion begins and then spreads into the main combustion chamber, assisted by turbulence created in the chamber. This system allows smoother, quieter running, and because combustion is assisted by turbulence, injector pressures can be lower, which in the days of mechanical injection systems allowed high-speed running suitable for road vehicles (typically up to speed of around 4,000 rpm). The prechamber had the disadvantage of increasing heat loss to the engine's cooling system and restricting the combustion burn, which reduced the efficiency by between 5-10% in comparison to a direct injection engine, and nearly all require some form of cold-start device such as glow plugs. Indirect injection engines were used widely in small-capacity high-speed diesel engines in automotive, marine and construction uses from the 1950s, until direct-injection technology advanced in the 1980s. Indirect injection engines are cheaper to build and it is easier to produce smooth, quiet running vehicles with a simple mechanical system, so such engines are still often used in applications which carry less stringent emissions controls than road-going vehicles, such as small marine engines, generators, tractors, pumps. With electronic injection systems, indirect injection engines are still used in some road-going vehicles, but most prefer the greater efficiency of direct injection.

Direct injection

Modern diesel engines make use of one of the following direct injection methods:

Distributor pump direct injection

The first incarnations of direct injection diesels used a rotary pump much like indirect injection diesels, however the injectors were mounted in the top of the combustion chamber rather than in a separate pre-combustion chamber. Examples are vehicles such as the Ford Transit and the Austin Rover Maestro and Montego with their Perkins Prima engine. The problem with these vehicles was the harsh noise that they made and particulate (smoke) emissions. This is the reason that in the main this type of engine was limited to commercial vehicles— the notable exceptions being the Maestro, Montego and Fiat Croma passenger cars. Fuel consumption was about fifteen to twenty percent lower than indirect injection diesels, which for some buyers was enough to compensate for the extra noise.

One of the first small-capacity, mass-produced direct-injection engines that could be called refined was developed by the Rover Group. The '200Tdi' 2.5-litre 4-cylinder turbodiesel (of 111 horsepower) was used by Land Rover in their vehicles from 1989, and the engine used an aluminium cylinder head, Bosch two-stage injection and multi-phase glow plugs to produce a smooth-running and economical engine while still using mechanical fuel injection.

This type of engine was transformed by electronic control of the injection pump, pioneered by Volkswagen Audi group with the Audi 100 TDI introduced in 1989. The injection pressure was still only around 300 bar, but the injection timing, fuel quantity, exhaust gas recirculation and turbo boost were all electronically controlled. This gave much more precise control of these parameters which made refinement much more acceptable and emissions acceptably low. Fairly quickly the technology trickled down to more mass market vehicles such as the Mark 3 Golf TDI where it proved to be very popular. These cars were both more economical and more powerful than indirect injection competitors of their day.

Common rail direct injection

In older diesel engines, a distributor-type injection pump, regulated by the engine, supplies bursts of fuel to injectors which are simply nozzles through which the diesel is sprayed into the engine's combustion chamber.

In common rail systems, the distributor injection pump is eliminated. Instead an extremely high pressure pump stores a reservoir of fuel at high pressure - up to 1,800 bar (180 MPa, 26,000 psi) - in a "common rail", basically a tube which in turn branches off to computer-controlled injector valves, each of which contains a precision-machined nozzle and a plunger driven by a solenoid,or even by piezo-electric actuators, which are found on experimental diesel race car engines.

Most European automakers have common rail diesels in their model lineups, even for commercial vehicles. Some Japanese manufacturers, such as Toyota, Nissan and recently Honda, have also developed common rail diesel engines.

Different car makers refer to their common rail engines by different names, e.g. DaimlerChrysler's CDI, Ford Motor Company's TDCi (most of these engines are manufactured by PSA), Fiat Group's (Fiat, Alfa Romeo and Lancia) JTD, Renault's DCi, GM/Opel's CDTi (most of these engines are manufactured by Fiat, other by Isuzu), Hyundai's CRDi, Mitsubishi's DI-D, PSA Peugeot Citroën's HDi (Engines for commercial diesel vehicles are made by Ford Motor Company), Toyota's D-4D, and so on.

Twin cylinder Petter type diesel engine

Unit direct injection

This also injects fuel directly into the cylinder of the engine. However, in this system the injector and the pump are combined into one unit positioned over each cylinder. Each cylinder thus has its own pump, feeding its own injector, which prevents pressure fluctuations and allows more consistent injection to be achieved. This type of injection system, also developed by Bosch, is used by Volkswagen AG in cars (where it is called Pumpe Düse - literally "pump nozzle"), Mercedes Benz (PLD) and most major diesel engine manufacturers, in large commercial engines (Cat, Cummins, Detroit Diesel). With recent advancements, the pump pressure has been raised to 2,050 bar (205 MPa), allowing injection parameters similar to common rail systems.

Types of diesel engines

There are two classes of diesel (and gasoline) engines: two-stroke and four-stroke. Most diesels generally use the four-stroke cycle, with some larger diesels operating on the two-stroke cycle, mainly the huge engines in ships (see also Nissan UD3, UD4 and UD6 engine series). Most modern locomotives use a two-stroke diesel mated to a generator, which produces current to drive electric motors, eliminating the need for a transmission. To achieve operational pressure in the cylinders, two-stroke diesels must utilize forced aspiration from either a turbocharger or supercharger. Diesel two-strokes are ideal for such applications because of their high power density--with twice as many power strokes per crankshaft revolution compared to a four-stroke, they are capable of producing much more power per displacement.

Normally, banks of cylinders are used in multiples of two, although any number of cylinders can be used as long as the load on the crankshaft is counterbalanced to prevent excessive vibration. The inline-6 is the most prolific in medium- to heavy-duty engines, though the V8 and straight-4 are also common.

As a footnote, prior to 1949, Sulzer started experimenting with two-stroke engines with boost pressures as high as 6 atmospheres, in which all of the output power was taken from an exhaust turbine. The two-stroke pistons directly drove air compressor pistons to make a positive displacement gas generator. Opposed pistons were connected by linkages instead of crankshafts. Several of these units could be connected together to provide power gas to one large output turbine. The overall thermal efficiency was roughly twice that of a simple gas turbine. (Source 'Modern High-Speed Oil Engines Volume II' by C. W. Chapman published by 'The Caxton publishing co. ltd.' reprinted in July 1949)

Carbureted compression ignition model engines

Simple compression ignition engines are made for model propulsion. This is quite similar to the typical glow-plug engine that runs on a mixture of methanol (methyl alcohol) and lubricant (typically castor oil) (and occasionally nitro-methane to improve performance) with a hot wire filament to provide ignition. Rather than containing a glow plug the head has an adjustable contra piston above the piston, forming the upper surface of the combustion chamber. This contra piston is restrained by an adjusting screw controlled by an external lever (or sometimes by a removable hex key). The fuel used contains ether, which is highly volitile and has an extremely low flash point, combined with kerosene and a lubricant plus a very small proportion (typically 2%) of igntion improver such as Amyl nitrate or preferrably Isopropyl nitrate nowadays.

The engine is started by reducing the compression and setting the spray bar mixture rich with the adjustable needle valve, gradually increasing the compression while cranking the engine. The compression is increased until the engine starts running. The mixture can then be leaned out and the compression increased. Compared to glow plug engines, model diesel engines exhibit much higher fuel economy, thus increasing endurance for the amount of fuel carried. They also exhibit higher torque, enabling the turning of a larger or higher pitched propellor at slower speed. Since the combustion occurs well before the exhaust port is uncovered, these engines are also considerably quieter (when unmuffled) than glow-plug engines of similar displacement. Compared to glow plug engines, model diesels are more difficult to throttle over a wide range of powers, making them less suitable for radio control models than either two or four stroke glow-plug engines although this difference is claimed to be less noticeable with the use of modern schneurle-ported engines.

Advantages and disadvantages versus spark-ignition engines

Power and fuel econonmy

Diesel engines are more efficient than gasoline (petrol) engines of the same power, resulting in lower fuel consumption. A common margin is 40% more miles per gallon for an efficient turbodiesel; for example, the current model Skoda Octavia, using Volkswagen engines, has a combined Euro mpg of 38.2 mpg for the 102 bhp petrol engine and 53.3 mpg for the 105 bhp — and heavier — diesel engine. The higher compression ratio is helpful in raising efficiency, but diesel fuel also contains approximately 10-20% more energy per unit volume than gasoline. Diesel engines are also much more economical than gasoline (petrol) engines when at low or idling engine speeds, when they use very little fuel due to the precision nature of the injector system. Unlike the petrol engine, diesels lack a butterfly valve (choke) in the inlet system, which closes at idle. This creates parasitic drag on the incoming air, reducing the efficency of petrol/gasoline engines at idle. Due to their lower heat losses, diesel engines rarely run the risk of gradually overheating if left idling for a long period of time providing the cooling system is in good order. In many applications, such as marine, agriculture and railways, diesel-engined vehicles are left idling unattended for many hours or sometimes days. These advantages are especially attractive in locomotives.

Naturally aspirated diesel engines are heavier than gasoline engines of the same power for two reasons; the first is that it takes a larger capacity diesel engine than a gasoline engine to produce the same power. This is essentially because the diesel cannot operate as quickly — the "rev limit" is lower — because getting the correct fuel-air mixture into a diesel engine quickly enough is more difficult than a gasoline engine [1]. The second reason is that a diesel engine must be stronger to withstand the higher combustion pressures needed for ignition, and the shock loading from the detonation of the ignition mixture. As a result, the reciprocating mass (the piston and connecting rod), and the resultant forces to accelerate and to decelerate these masses, are substantially higher the heavier, the bigger and the stronger the part, and the laws of diminishing returns of component strength, mass of component and inertia - all come into play to create a balance of offsets, of optimal mean power output, weight and durability.

Yet it is this same build quality that has allowed some enthusiasts to acquire significant power increases with turbocharged engines through fairly simple and inexpensive modifications. A gasoline engine of similar size cannot put out a comparable power increase without extensive alterations because the stock components would not be able to withstand the higher stresses placed upon them. Since a diesel engine is already built to withstand higher levels of stress, it makes an ideal candidate for performance tuning with little expense. However it should be said that any modification that raises the amount of fuel and air put through a diesel engine will increase its operating temperature which will reduce its life and increase its service interval requirements. These are issues with newer, lighter, "high performance" diesel engines which aren't "overbuilt" to the degree of older engines and are being pushed to provide greater power in smaller engines.

The addition of a turbocharger or supercharger to the engine greatly assists in increasing fuel economy and power output, mitigating the fuel-air intake speed limit mentioned above for a given engine displacement. Boost pressures can be higher on diesels than gasoline engines, and the higher compression ratio allows a diesel engine to be more efficient than a comparable spark ignition engine. Although the calorific value of the fuel is slightly lower at 45.3 MJ/kg (megajoules per kilogram) to gasoline at 45.8 MJ/kg, diesel fuel is much denser and fuel is sold by volume, so diesel contains more energy per litre or gallon. The increased fuel economy of the diesel over the gasoline engine means that the diesel produces less carbon dioxide (CO2) per unit distance. Recently, advances in production and changes in the political climate have increased the availability and awareness of biodiesel, an alternative to petroleum-derived diesel fuel with a much lower net-sum emission of CO2, due to the absorption of CO2 by plants used to produce the fuel.

The two main factors that held diesel engine back in private vehicles until quite recently were their low power outputs and high noise levels (characterised by knock or clatter, especially at low speeds and when cold). This noise was caused by the sudden ignition of the diesel fuel when injected into the combustion chamber. This noise was a product of the sudden temperature change, hence why it was more pronounced at low engine temperatures. A combination of improved mechanical technology (such as two-stage injectors which fire a short 'pilot charge' of fuel into the cylinder to warm the combustion chamber before delivering the main fuel charge) and electronic control (which can adjust the timing and length of the injection process to optimise it for all speeds and temperatures) have almost totally solved these problems in the latest generation of common-rail designs. Poor power and narrow torque bands have been solved by the use of turbochargers and intercoolers.

|

||||||||||||||||||||||

| JCB DIESELMAX LSR PROJECT | |||

|

|

Please click on the links above to find out about these famous automotive makers. If your company is not included and you would like to be listed, please let us know.

UK VEHICLE INSURANCE ONLINE A - Z

No matter what car, van or bike you drive, we're all looking for great value and quality in our UK motor insurance? But who is the best - who is the cheapest and who offers the great service in the event of a claim?

See the insurance companies below who claim to offer competitive cover at sensible prices, our guide to the jargon and tips for cutting your quote - Good Luck:-

|

ADRIAN FLUX - SPECIALIST INSURANCE ASDA CAR INSURANCE CENTRAL DIRECT VEHICLE INSURANCE EQUITY RED STAR MOTOR POLICIES HALIFAX ONLINE CAR INSURANCE HSBC car insurance

|

MORE THAN - Sun Alliance N.I.G CAR INSURANCE PROVIDENT FINANCIAL QUOTE ZONE CAR INSURANCE

|

A taste for adventure capitalists

SMART-CHARGER - Potentially the world's fastest electric car: 400mph using energy from nature. Featuring built in energy cartridge swapping system, charged using renewable solar energy. A project in waiting in PR terms to celebrate the banning of petrol and diesel cars in Europe and the UK from 2030.

AUTOMOTIVE A TO Z CHARITY CONTACT EVENTS HOME SITE INDEX

The

content of this website is copyright © 1991 and 2020 Electrick

Publications. All rights reserved. The bluebird logo  and

name Bluebird

and Blue Max are trademarks. The BE2 and BE3 vehicle shape and

configuration are registered designs ®. All other trademarks

are hereby acknowledged. Max Energy Limited is an educational

charity.

and

name Bluebird

and Blue Max are trademarks. The BE2 and BE3 vehicle shape and

configuration are registered designs ®. All other trademarks

are hereby acknowledged. Max Energy Limited is an educational

charity.