|

THE 'BORZOI' - BODYWORK

|

|

HOME | INDEX | AUTOMOTIVE | BLUE PLANET BE3 | ELECTRIC CARS | ENERGY | FORMULA E | NEWS | SOLAR CARS |

|

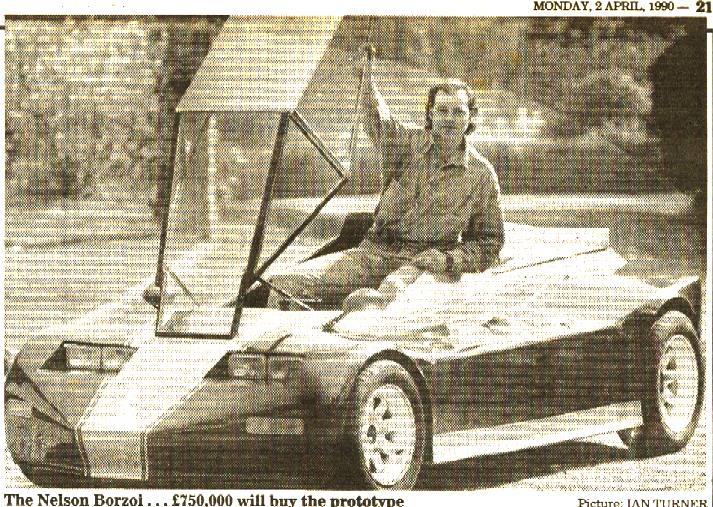

Nelson Kruschandl making the Borzoi's alloy bodywork

A good way to learn how to form metal, is to build a car from scratch. Be prepared to get dirty and to make a few mistakes. Ally sheeting is expensive, so also be prepared to get in trouble with the girlfriend. Ally is softer than steel and easier to form, but is much harder to weld, and you are likely to need specialist welding equipment. You'll also need to sharpen your concentration. The quality of a weld is dependent on your skill level.

I was a jeweler for a time, hence already used to small tolerances, and used to forming metal into shapes. You may want to try bending wire into accurate shapes before trying to shape panels from sheet metal. If you cannot weld, use pop rivets. Some of the panels in the body above were formed over my knee. For tight radius bends use a vice and angle iron to fold the metal.

With practice and precise marking using fine tipped felt markers (Projector) you can make surprisingly nice parts. Remember which side of the line you are bending from - no worries. I used tin snips and an electric jigsaw to cut the sheets. When cutting frequently blow the filings away to stop surface marking.

The Borzoi's aluminium body panels were hand formed on the frame and over any convenient shaped surface, but mostly over round and square section steel tubes. You'd need a folding machine if you were going to make this a career. I didn't build enough cars to warrant that expense. In any event, I soon discovered the joys of glass reinforced plastic.

To make a nice looking car, you need a good eye, some long straight edges and a sharp scribe. Be careful to wash off any felt tip pen lines with thinners after making the panels, because they leach through primer into your topcoat. You'll also need a workbench or table large enough to mark out 8' x 4' sheets of metal. Two tables the same height is preferable.

Handle the metal sheets with care. Mark out accurately and check your measurements. I sometimes do this two or three times, where I have cut long or short before thinking I couldn't get it wrong. You will make a mistake or two. We are only human. the secret is to recognize your weaknesses and allow for them. I also have strengths. Learn your strengths and trust in them. I'm now confident that I can build virtually anything. When I first started, I doubted this. It's just a matter of scaling up from making models.

Cutting with a jigsaw eliminates shear stresses that tin snips induces. If cutting fine strips with snips, make sure the curl edge is the one being discarded.

See the Car development build stages of the Borzoi prototype car using these links:-

Borzoi Chassis | Borzoi Bodywork | Borzoi Joystick | Borzoi Styling | Borzoi Engine

CHASSIS | LOADING-SERVO | CARTRIDGE | MOTORS | INSTRUMENTS | WIND-TUNNEL

The driver sits at the rear dragster fashion, the battery cartridge is in the front all the way to the nose cone. Check out the battery cartridge exchange sequence below.

THE BLUE BIRDS OF HAPPINESS

The bare car bodywork was etch primed, then finished in a two tone metallic silver and charcoal paint scheme - using a 2 pack base and clear coat system. Etch priming of aluminium is essential, where protective oxides form quickly preventing good paint adhesion. Once there the acid in the etch primer has keyed paint to the metal, the following coats of primer and 2-pack will bond nicely.

I'm not that good at spray painting. It's an art. The paint must be at the right temperature and viscosity - and it pays to use a quality gun. Also, the compressor needs to have a good output. Mine didn't. I made my compressor unit myself by bolting a small tire pump to a large air tank and upping the gear ratio. It worked fine, provided that you waited in between coats of paint for the poor old tire compressor to raise the tank pressure. I found that I could not only make a cup of coffee, but could drink it in the time this took.

Eventually, I managed to obtain a reasonable full gloss coat without runs. When using metallic paint as base and clear coat, there is not much time allowed between spraying the colour coat and applying the clear coat. If you don't allow enough time the colour coat will not set enough. If you leave it too long, you will lose the chemical bond between layers and one day soon the lacquer will peel off.

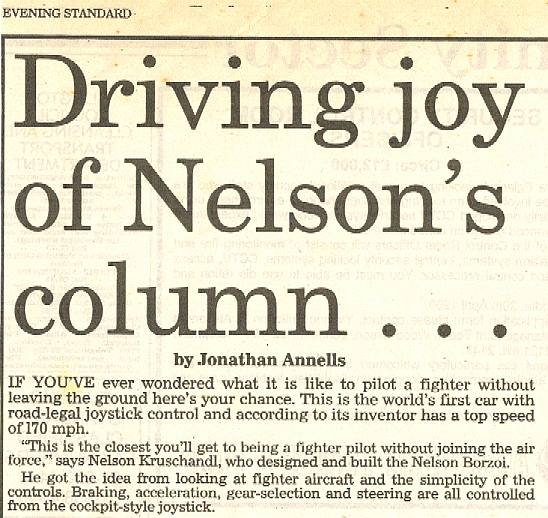

As an inventor, you have to become a jack of all trades: draughtsman, mechanic, welder, machinist, painter, etc. Either that, or your cars will end up costing a fortune. I'm also a patentee. This came about because I didn't want to use a conventional steering wheel. Basically, I like doing things differently. It seemed to me that a joystick was a simpler arrangement - and it is, but the rack and pinion steering gear has its advantages, such as reducing the strain of steering on heavy vehicles.

I can't recall why I applied for a patent, and sometimes I wish I hadn't because of the cost and really these days for a lone inventor - you are wasting your time - unless you are independently wealthy. I was not wealthy at the time, I'd just got married and bought my first house in Polegate, Sussex. Although my wife married me for my creativity (she was a gifted artist), that soon wore off as money went to pay for patents (which spirals) with no sign of any return - and with a mortgage around your neck it's no laughing matter. I'm surprised my marriage lasted so long. We also suffered from negative equity thanks to Black Monday.

Mind you, if I hadn't been through the mill, a sort of innovation apprenticeship, I'd never have crafted some of my favourite shapes. You can see my other (electric) vehicle designs on this site. I conceived the vehicle below and hope the team will be able to build it one day. Even it it's only because it looks so nice.

This car was quick. Before parting with it, Nelson removed the tuned fuel injected V6 2.8 litre Peugeot engine and put in the bog standard twin choke Renault 2.5 litre V6. The power steering rack and pumps, etc, were also retained for incorporation on a two seat sports car, that unfortunately never saw the light of day.

|

|

EDUCATION | E. CYCLES | SOLAR CARS | SOLAR CAR TEAMS | SOLARNAVIGATOR |

|

This

website is copyright © 1991- 2014 Electrick Publications. All rights

reserved. The bird logo Max Energy Limited is an educational charity working for world peace. |