|

Nelson was sufficiently advanced with the development of his

battery cartridge refueling system and the design of a demonstration racing

design to file a patent application in the winter of

1990. The above letter from the Patent Office confirms receipt of Nelson's

application and the date of filing as 21 November 1990.

The obvious way to promote

the performance of cars using his patent applied for, refueling system was to

follow in the footsteps of Henry Ford, who also thought to set a land speed

record on a frozen lake to draw attention to the performance of his

cars.

Nelson had already

constructed a prototype vehicle to demonstrate his patent mechanical joystick

control which replaced the usual floor pedals and steering wheel (patent GB2218187)

This car, built around his joystick control was named the 'Borzoi' after the

Russian hunting dogs famed for their grace and speed. The 'Borzoi"

was no slouch, topping 175mph in some tests using a 2.8 litre injected V6 petrol

engine.

A patent was finally granted

to Nelson for the battery cartridge refueling system in April of 1995 under

patent number: GB2253379.html

This

patent has now lapsed under the rule that many inventors view as unreasonable,

that patents only have a 20 year shelf life. The 20 year time frame is simply

not realistic where some technologies are more than that ahead of their time, so

will not have any commercial value until the patent has lapsed.

Thus the act of filing a patent is in effect giving away information for free.

If

you are an inventor you may wish to consider this and not file, for the

protection you are seeking, the state will deprive you of under the present

system. The system needs to be changed to take into account that patents

should only start running from when they are first commercially exploited

- not from when they are first filed.

Email:

or phone UK:

or phone UK:

+

44 (0) 1323 831727

+44

(0) 7842 607865

Intelligent

Battery Support System

GB2253379

patent extract:

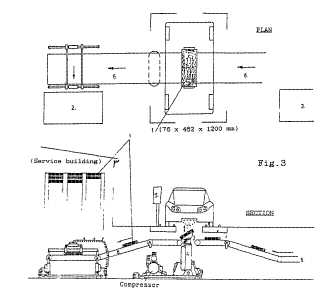

The

system includes a quick release battery loading/unloading mechanism using

standardised battery-power-pack(s) coupled with an in-vehicle energy

management instrument and information exchange system capable of

transferring the customer's requirements, identity and energy used to a

service station terminal, allowing extended operating range and

eliminating delays associated with charging traction batteries in situ.

The wheel rim, hub, axle and bearings may incorporate electrical windings,

laminations, brushes, magnetic components to make a complete drive motor

and such wheel-motors may be provided at the front or the rear or on all

wheels. Solar cells for charging the vehicle battery may be incorporated

into body panels which attach to a supporting frame on the vehicle.;

Recharging may also be by regenerative braking, from an external supply,

by an on-board engine-powered generator or by use of a fuel cell. The

vehicle may have a suspension system in which the upper or lower wishbone

also serves as a spring. A joystick may be provided for controlling the

steering, braking and acceleration. The seating arrangement may be 1-2-1

with a central driver and central rear passenger.

Title: Comprehensive

electric motor road vehicle system

Patent

Office: United Kingdom Intellectual

Property Office (IPO)

Application Number: GB19920000787 19920115

Publication Number: 2253379 (A)

Application Date: 1992-01-15

Publication

Date: 1992-09-09

Full

Text at United Kingdom Intellectual Property Office (IPO)

Bibliographic

data: GB2253379 (A) ― 1992-09-09

Comprehensive

electric motor road vehicle system

| Page bookmark |

GB2253379

(A) - Comprehensive electric motor road vehicle

system |

| Inventor(s): |

KRUSCHANDL NELSON

JAMES +

(NELSON

JAMES * KRUSCHANDL) |

| Applicant(s): |

KRUSCHANDL NELSON

JAMES +

(NELSON

JAMES * KRUSCHANDL) |

| Classification: |

|

| Application number: |

GB19920000787 19920115 |

| Priority number(s): |

GB19920000787

19920115; GB19910003057 19910213 |

| Also published as: |

|

Abstract of GB2253379 (A)

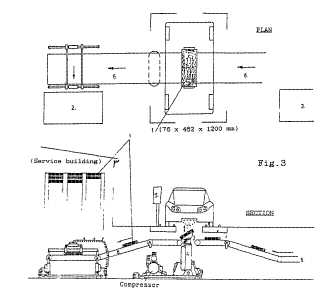

Please

note that this system in not suitable for the low cost 'Universal'

service forecourt

being

proposed for worldwide distribution - It was NK's example in 1990

GB2253379

is referenced by 13 patents and cites 8 patents.

B60

K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 1

PATENT

DESCRIPTION

I, NELSON JAMES KRUSCHANDL, Inventor, of "Oakwood", Lime Park, Church

Road, Herstmonceux, East Sussex, in Great Britain, do hereby declare the

inventions, for which I pray that a patent may be granted to me, and the methods

by which they are to be performed, to be particularly described in and by the

following description This patent document may be seen as unusual inasmuch as it

contains and brings together a number of separately patentable new inventions,

which may be used on their own, or in combination with one another, or in

combination with any known method of electrically propelling a motor road

vehicle.

However, it is the considered viewpoint of the inventor that each of the

separate new innovations described in this patent description and the claims

following, are associated in such a way as to be bound together by an overriding

unity in a Comprehensive Electric Motor Road Vehicle System, (to be known

henceforth as the "Wolverine" system) if the system is to be described

and enacted in the most useful form/combination(s).This fact in no way

diminishes or restricts the uses or applications to which those separable

inventions may be put to in the future, and the disclosure by the inventor in

this patent specification and this application should in no way restrict and is

not in any way shape or form to be taken as restrictive, so far as each separate

stage/step of the intellectual development of this present system may be used in

the development of electrically powered transport systems, lest the inventor be,

in effect, penalised by the state and the patent system for his efforts to make

public his progress, as clearly this is the very reason the patent system has

been evolved. The disclosure of these inventions is made with the intention that

in so doing, he will pass on the benefit of his progress to his fellow man and

be rewarded through normal lawful commercial enterprise.

These inventions relate to an electrical drive motor, electrical drive motor

cooling system, brake/regenerative-brake application and control and/or power

supply/collection and/or power generation arrangement/system and/or a multi-fuel

fuel conversion capability and/or a vending system for electrically powered

motor road vehicles for use on the public highways as transportation and for

transportation where: - a) The drive motor and/or regenerative braking system is

constructed as part of (incorporated into) the wheel/hub/axle/brake assembly as

an integral part of the wheel/hub/axle, to form a wheel/hub/axle-motor and

brake.

b) The wheel/hub/axle-motor and brake assembly or wheel-motor, is cooled by

natural airflow over an open motor design; or is cooled by fan assisted airflow

through a ducted motor design; or is cooled by heat transfer from the motor

components and especially the windings via a heat-conductive paste to a

B60

K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 2

PATENT

DESCRIPTION CONTINUED

finned

radiator/heat-sink; or is cooled by circulation of a heat-conducting liquid

medium over or through the wheel-motor components.

c) The method of providing power for the electrically powered vehicle is aided

by a direct percentage contribution from high efficiency solar power panels

converting light to electrical energy while the vehicle is driven, and a

percentage contribution which is stored in e) below, when the vehicle is

stationary or parked (assuming adequate sunlight conditions in both instances).

These solar cells or photovoltaic effect cells can be of the Gallium-arsenide,

Cadmium, Silicon, or any other known combination of elements or compounds

converting light to electrical energy.

d) The method of providing power for the electrically powered vehicle is aided

by a regenerative braking system, providing electrical energy which is stored in

e) below, as a contribution or percentage of the total drive power requirement,

where/when the main drive motors are switched electrically and/or electronically

to a generating/charging mode progressively or in stages, according to brake

lever loadings/driver inputs and returned to drive motor mode as demanded by

accelerator loadings/driver inputs. Said generated electrical energy being

suitably transformed/electrically/electronically upgraded to a value suitable

for charging, hence storage in the vehicles 5 power-pack storage battery.

e) The method of providing power for the electrically powered vehicle is by

drawing on stored electrical energy from electroreversible cells/batteries of

the lead-acid, nickel-cadmium, sodium-sulphur or any other type/combination of

secondary cell chemically storing electrical energy. These storage cells being

charged by any known method of charging batteries and especially by c) and d)

above and h), i), and o) below and the battery bank also serving as a buffer in

the system for contribution charging purposes.

f) The method of providing power for the electrically powered vehicle is from a

conversion of gasses/liquids/liquid gasses, or dissolved gasses and/or liquid

solutions, to electrical energy in a refuellable primary cell or battery of

cells or fuel cells, as accompaniment to c), d) and e) above, or as the sole

power generator/supply, the system being particularly applied as a small

self-contained unit to form a compact generator, the compact generator charging

the onboard power-pack(s) to form a hybrid vehicle variant with an alternative

fuel source to that normally associated with hybrid (i.e. a petrol-electric

vehicle) electric vehicles. The compact generator also being designed for use

with the gas fuel of hydrogen contained in the storage medium, as explained in

g) below.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 3

PATENT DESCRIPTION CONTINUED

g)

The method of storing hydrogen gas for use in a gas fuelled form of fuel

(primary) cell in f) above is in the form of a hydride in combination with metal

alloys in the form of: pellets, their construction or make up being; porous

spongy metal plates; an open celled microcellular slab/block; a

wire-wool-stranded mass, all of these metallic forms designed so as to increase

the surface area available for reaction with the hydrogen gas. The reactive

metal form being encapsulated by or contained in a sealed pressure vessel so as

to form a gas or fuel tank from which gas may be drawn when warmed/liberated and

fed into the fuel cell reaction chamber.

The method of providing power for extended range use is by using an onboard

dynamo/alternator coupled to a small internal combustion engine of the

reciprocating (petrol, diesel) or turbine variety, or an external combustion

engine of the Stirling engine type (R. Stirling 1816 pat. no. 4,081) to form a

compact generator. The compact generator charging the onboard battery power

pack(s) in e) above, to form an electric vehicle commonly referred to as a

hybrid.

i) The method of providing power for extended range usage is by arranging for

the electroreversible storage battery of cells in e) above to be exchangeable by

a quick release/loading/unloading mechanism/system so that said battery power-pack(s)

that have been exhausted of charge may be exchanged with/for fully charged

battery power-pack(s) which also fit dimensionally, use the same loading

mechanism and offer similar performance and capacity as a standardised

specification battery pack or packs or as a battery store power-pack

specifically intended for use by the vehicle so equipped. These standardised/replacement

battery store power-packs or specially designed replacement battery store

power-packs being made available at roadside vending/charging/service

stations.The standardised or specialised battery store power-packs optionally

being replaced with a spare pack normally kept and charged at a home base.

j) The method of regulating and controlling power application to the drive motor

is by electrical and/or electronic solid-state:

switching/pulsing/chopping/amplifying and/or variation/modulation/wave

generating/devices circuits, units, systems, means.

k) The method of providing variable tracking or differential effect (where

required), is by proportional speeding up, or slowing down, of left or right

tracks by taking instructions from the physical position of the steering

controls via a sensor/transducer and a direct link with the vehicle speed

controllers, and/or alternatively is by an indirect microprocessor/computer

electronically controlled motor-wheel speed

correction/synchronization/orchestration, and from steering control sensor

variation/inputs/demands, and/or

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 4

PATENT

DESCRIPTION CONTINUED

alternatively

is by interactive self regulating and compensating circuitry designed to prevent

excessive unloaded speeding of any drive motor and further designed to even out

the distribution of driver-demanded power between the number of drive motors on

an axle.The system also acting as an anti-lock brake skid preventing device.

1) An alternative method of commutation is by using electronic switching of

current to the armature windings, back e.m.f. and driver inputs providing

essential control inputs to high speed microchip processor(s), enabling high

performance applications.

When permanent magnets or self-exciting windings are used as the field, attached

in the wheel rim in lower power applications, this method would eliminate carbon

brushes from the wheel motor altogether. If powered field windings are required

as, for example, in higher output or longer life applications, only slip rings

will be required for supply.

m) The method of providing power for the electrically powered vehicle is a

combination of a, b, c, d, e, f, g, h, i, j, k, 1, n, or o, in any order,

quantity or association and/or any other known method of providing or applying

electrical motive power to form a practical, comprehensive electric

motor-land/road-vehicle system.

n) A method of keeping constructional complications to a minimum and further

reducing vehicle weight is by incorporating the battery pack storage, location

and quick release/pick-up system into or as part of the chassis' main structural

members/components.

o) A method of providing a vehicle with a multi-fuel capability, that is to say

the ability to use more than one type of fuel as the source of motive power is

by adopting a dimensionally standard loading, securing mechanism with electrical

connections also in a dimensionally standard and fixed position in relation to

the securing mechanism, so that any form of generator and/or electrical store so

designed to comply and be compatible with the dimensional requirements, may be

loaded/connected into/onto/with the vehicle power supply circuitry and controls.

HISTORY

The development of an efficient electrically driven motor vehicle has been

overshadowed during the past century by progressive improvements to vehicles

powered by internal combustion engines. The reasons for this are manifold:

ONE - The necessary technology had not, up until now, been available to make an

electrically powered vehicle which could compete with its internal combustion

rivals on range, performance and practicality.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 5

PATENT DESCRIPTION CONTINUED

As long ago as 1897 Ferdinand Porsche, then under the employ of Ludwig Lohner,

was presented with the opportunity to design and build a battery powered car

using hub-mounted electric motors. Unfortunately, the range of 32 miles at 9 MPH

limited applications of the vehicle known as the "Lohner-Porsche

Chaise". Later, in 1901, Porsche developed this theme further by replacing

the heavy and cumbersome batteries with a generator unit powered by a Daimler

petrol engine. He still used electric motors incorporated in the front wheel

hubs and this vehicle known as the 1901 "Lohner-Porsche" achieved a

maximum speed of 55 MPH. The 1901 "Lohner-Porsche" was probably the

first petrol-electric hybrid in history.

In Great Britain, the Luton firm of E.W. Hart built their "Toujours

Contente" and "Presque Contente" models featuring a Lohner-Porsche

motor in each hub making them, in all probability, the first four-wheel drive

cars. In 1907, Mercedes joined in the race to develop an electric car.

Porsche was commissioned by them to design their "Mercedes-Mixte"

model, which was a petrol-electric hybrid.

By any standards the performance attained by these electric vehicles was, at the

time, astonishing. The world land speed record, held by Jenatzy 1899., was only

65.79 miles per hour rising to 121.57 MPH in 1906 when the steam powered Stanley

Rocket stole the lead. If Porsche had had the knowledge of electronics, solar

collectors, steel wheel construction and modern batteries, most of us would now

probably be driving around in electrically propelled cars and the internal

combustion powered vehicles we take for granted, would have only commercial and

perhaps sporting applications. Proof of this statement can be seen in the

absence of internal combustion engines in any modern permanent industrial

installation. In other words, if electrical power can be made practically

available in a given application it is almost always used in preference to other

energy sources.One reason for this is the efficiency with which electric

machines convert electric power into useful motive power. Commercial generating

installations often achieve efficiencies of 98%.

Other factors such as convenience, quietness and cleanliness must also be taken

into consideration.

Whilst 1,575 electric vehicles were manufactured in 1900 in the United States

compared with only 939 gasoline powered vehicles, the trend was soon to reverse.

Electric vehicles were very popular with women because of the difficulties of

starting an internal combustion engine with a manual crank.

Then in 1911 the electric self-starter was introduced by Cadillac. Soon other

manufacturers incorporated the self-starter onto their piston engined vehicles

and that particular problem was solved opening the way for practical everyday

use of I.C.E. powered automobiles by the fair sex.

B60

K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 6

PATENT DESCRIPTION CONTINUED

After 1930 production of most electric vehicles had stopped, being regarded

largely as museum pieces. One exception was the "Detroit Electric",

built by the American Anderson

Electric Car Co., which continued to be produced to special order until 1939.

More recently, and as a direct result of soaring petrol prices and the very real

possibility of petrol rationing in the 70s, experimental studies have led to

promising EVs being built and tested by, for example, the Electricity Council

who evaluated the "Enfield" vehicle in 1973 - 1976. The idea was to

use the vehicle for meter-reading duties.

The Electric Power Research Institute (Palo Alto) suggested that a modern day

electric vehicle represents a major new revenue source for electric utilities.

It has been estimated by them that each vehicle would use the equivalent energy

equal to or exceeding that used annually by the average household. This would

help solve the problem of power station load management as charging of EVs from

domestic supplies would normally be carried out overnight from off-peak

supplies.

This practice could mean power stations were able to operate more efficiently

and would not necessarily require -any expansion to cope with demand. General

Motors are at this time running fleets of essentially overnight charged vehicles

("G" Wagons), in selected city areas for just such evaluation.

Power taken directly from nature as the conversion of sunlight has also been

investigated but without any practical form of application. Vehicles running on

sunlight only cannot be used all the year round because of unpredictable

fluctuations in the weather and presumably the application of "Murphy's

Law".

Nevertheless, research has continued apace with vehicles mainly intended as

competitors in the Pentax World Solar Challenge, a race across Australia, north

to south, from Darwin to Adelaide, a distance of 1,875 miles. Vehicles competing

in this race can only be described as thoroughbred out and out racing machines

with little or no practical application. For example GMs "Sunraycer"

and the Solar Honda are both pure teardrop aerodynamic exercises arranged around

the forward seated driver with a massive flattened tail to accommodate a very

large solar panel collection area.

However, these developments have proved that electricity from the sun is a very

real energy source just waiting to be tapped.

There are two main problems associated with the purchase and running of

electrically powered vehicles planned for launch by mainstream manufacturers in

the near future. Firstly, state of the art battery developments still allow

ranges of only 60 - 150 miles. This limits the market for electric vehicles to

those who only use cars for short distances/round trips.

The assumption being that a vehicle will return to a home base where it can be

trickle-charged from a domestic electricity supply. Commuters and families

wanting to travel longer

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 7

PATENT DESCRIPTION CONTINUED

distances

are not catered for. This is clearly a problem and limits the electrical vehicle

as a practical proposition.

Secondly, the replacement price of a new battery pack after approximately three

- four years use (20,000 - 40,000 miles), has to be taken into the calculations

of total fuelling costs.

This fact detracts from the obvious financial advantages of using a renewable

fuel source and is seen to be an obstacle to the economical running of an E.V.

TWO - There has not, before now, been the urgent need for an alternatively

fuelled method of transport. In the early days of motor vehicle development oil

derived fuels were plentiful, as nobody had then found a volume use for the

refined petroleum spirit. It was because of the growing popularity and

practicality of the internal combustion engine that a market for the otherwise,

unused by-product, was created. The abundant distribution of petroleum deposits

in the Earths sub-strata and competition from oil producing countries has kept

petrol supplies reasonably priced. Indeed petrol/oil fuels have been taken for

granted as a cheap source of energy by most industrial nations and is the device

by which economies are kept buoyant. Thoughts of this fuel supply running out

seem to have been conveniently filed for later attention.

Exploration for petroleum oil deposits continues expeditiously in order to

replace existing wells that are being drained and as a result the price of

petrol for transportation is bound to rise. So far, however, any increase has

not been sufficiently large to discourage the world's motorists from wasteful

journeys and any increases imposed, certainly have never, in real terms,

reflected any harmful effects to the planet Earth and/or the cost of

cleaning-up, or righting, pollution from oil spills, etc.

Supplies of oil for refining to petroleum are subject to political and other

market forces which can seriously damage any governments's attempts at economic

planning and stability for their country. In recent times pressure for the

continued supply of cheap oil, to meet many countries energy requirements, has

caused a situation of international concern in the Middle East. This area can

accurately be described at this time as the oil well of the world. Any reduction

of dependency on this resource would be a good thing.

In any event, oil is a non-renewable fossil reserve which is due to run out in

the near future. There is, therefore, a pressing and long overdue need for the

development of an alternative to the internal combustion engine.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 8

PATENT DESCRIPTION CONTINUED

THREE - It has only recently become recognised that emissions from the

combustion process could be permanently harmful to world ecology. The burning of

hydrocarbon fuels has been associated with extensive world-wide carbon

dioxide/monoxide pollution which has been linked with a condition of global

warming. Global warming, it is argued, could have dire consequences for the

future of the planet Earth and if allowed to continue at its present rate may

re-draw the hospitable borders on maps of the future. The internal combustion

engine is a major contributor to this pollution, producing about 20% of the

greenhouse effect Carbon Dioxide gas, 75% of the poisonous Carbon Monoxide and

50% of the smog forming Hydrocarbons.

In allowing this situation to continue unquestioned, we'are de facto accepting

the inevitability of damage to our environment, as the price necessary to be

paid for our present and continuing motoring pleasure.

Urban smog caused by fumes from the I.C. engined car has now become such a

problem in hot climates that they pose a serious health hazard. Huge yellow

clouds hang over Los Angeles on bright days formed by the action of sunlight on

Nitrogen Oxides and Hydrocarbons, to form Ozone. Parents quite rightly keep

children in on hot days to prevent inhalation of the carcinogenic fumes which

give rise to all manner of breathing disorders. This has promted bodies such as

the "Clean Air Resources Board" and "South Coast Air Quality

Management" in the state of California, U.S.A. to help introduce

legislation designed to induce car makers locally and exporters worldwide to

manufacture and offer to the public the option of a clean automobile. It must be

remembered that worldwide production of vehicles runs to around 130,000 units

per day.

Los Angeles is particularly a problem area having a population of some

12,000,000 people driving 8,000,000 vehicles. Probably the highest concentration

of vehicles per square mile or per person in the world. Accordingly, this would

seem a logical place to start corrective measures and may prove to be a much

needed model for the rest of the world to follow. At this time it is recognised

that electricity offers the only real solution to clean motoring.

For the above reasons, a system of environmentally harmonious transportation

(preferably using renewable energy) is quite clearly a desirable proposition

both commercially and ecologically.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 9

PATENT DESCRIPTION CONTINUED

To date, sporadic efforts have been made towards developing alternative forms of

transport, mainly by forward thinking research organisations, with a

"green" rather than commercial bias. This has led to experimental

battery powered vans and cars which require overnight charging from "off

peak" mains electricity supplies as their only source of power input.

The race so far has been confined to seeing who could squeeze in the biggest

battery pack; this seemingly being the only solution to extending ranges and

improving speeds although research into batteries of cells with higher charge

densities is helping to reduce the size and weight of those battery packs. The

making of power in electricity generating stations, gives us the easier option

of centralised pollutant removal/treatment as an interim solution, during the

long-term phasing out of old technology.

Some manufacturers have chosen to experiment with alternative renewable fuels

that can be used in the internal combustion engine, thus capitalising on the

large numbers of vehicles in existence using that system as the prime mover.

Recent examples of these alternatives are: Alcohol, Methanol, Propane, Methane

and Hydrogen, although there are many others. The case for hydrogen is, on the

surface, extremely good. Closer analysis of the conversion chain reveals marked

inefficiencies of the system that manufacturers seem prepared to overlook,

because hydrogen vehicles can be refuelled in about 15 minutes safely using the

hydride pellet storage method if pumped cooling water is used (see Mercedes 310

minibus).

Water is split into hydrogen and oxygen using electricity by electrolysis

(hydrogen derived from fossil fuels being very expensive and counter

productive). The liberated hydrogen gas is then attached to the metallic sponge

pellets (catalyst) in the vehicle's fuel tanks, forming a hydride.

The gas is released from the hydride state by the application of heat from the

I.C. engines exhaust pipe. Then the original weakness in the chain becomes

apparent, as any internal combustion powered land vehicle can only effectively

deliver a miserly 20% of the original fuel energy supplied to it. By contrast,

electrically powered land vehicles regularly achieve 70% efficiencies through

their drive trains.

The only real drawback being the time taken to refuel/charge the batteries of a

conventional electric vehicle - normally 8 to 10 hours.

It is becoming universally realised that fossil fuel reserves ought to be

safeguarded for more important tasks where renewable energy sources cannot be

used at this time (i.e. travel by flight), or as insurance against a future

situation which may prevent us using naturally abundant renewable resources.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 10

PATENT DESCRIPTION CONTINUED

IDENTIFIED PROBLEMS

There is no fully integrated or comprehensive electrically powered vehicle

system suitable as a replacement to traditional methods of transport. The

systems being developed by manufacturers of motor vehicles at this time are half

way, add-on, conversions using existing production vehicle technology, which in

no way makes the best use of newly developed advances in technology in a

format/system specifically designed from the ground up as a comprehensive

electrically powered vehicle system/package. This approach is reflected in the

poor performance figures quoted by manufacturers for their first batch of Los

Angeles qualifying vehicles.

The main weaknesses in the design of electrically powered vehicles to date are

the restriction on range and performance; the result of long refuelling times,

without any method or provision for refuelling along the public highways. If the

refuelling problem can be overcome, then higher performance will follow and

electrically powered vehicles may then offer practical long range motoring.

The other critical area of design and application for attention is the way

electrical power from motor machines is brought to the vehicles tyres; that is

the efficiency of the drive system.

INNOVATIONS

These present inventions replace and/or incorporate known methods of electrical

motivation, energy storage and vending with:- recent technological advances in

solar cell, fuel cell, electrochemical storage cells; and/or a new

motor/wheel/hub/axle arrangement and control incorporating the latest advances

in electric machine/motor design and electronic power control or handling;

and/or a new battery-power-pack loading and unloading or refuelling system;

and/or a new add-on multi-fuel capability; and/or a new battery-power-pack

vending system; and/or a new solar cell deployment, to form a workable and

practical electrically powered motor road vehicle and energy supply system,

which can either supplement or replace altogether the internal combustion engine

powered motor road vehicle.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 11

PATENT DESCRIPTION CONTINUED

METHOD OF INTEGRATION AND APPLICATION

COMBINED WHEEL, HUB, AXLE, BRAKE AND MOTOR DRIVE:

The electrical motor design/make-up of this present Wolverine system, which may

include the following components depending upon motor type, A.C., D.C. or

hybrid: windings, cores, armature, stator, rotor, commutator, slip-rings,

permanent magnets, cages, spiders, brush assemblies, filters, guards and

regenerative braking parts, cooling fans, cooling sinks, cooling jacket(s) and

any other component normally found/needed in an electric motor machine, are

incorporated in'the wheel rim, hub and axle that would normally be found on a

conventional vehicle set-up (live or independent axles).

This has the advantages of :1) SAVING WEIGHT - by sharing and combining the uses

of basic component parts found in a normal wheel/hub/axle assembly with the

motorising electrical components needed to complete the assembly so becoming a

motor-wheel/hub/axle or motor-wheel.

For example: - The stub shaft shares the commonality of function with the motor

spindle or shaft; The wheel rim shares the commonality of function with the

motor casing or yoke; The wheel spokes/central pressing/casting, shares the

commonality of function with the motor spider and in some cases, casing; The

wheel bearings share the commonality of function with the motor bearings. By

this means (method of incorporation), motorising components may be added to a

wheel hub assembly adding only 0.5 - 51bs per horsepower output (0.3 - 3kgs per

kilowatt) or less, depending on the technology applied, to make a light

motorised wheel or wheel-motor.

A standard vehicle (small sedan deployment example) requiring a total of 20kw

(26.8HP) output, would require 4 X 5kw wheel motors (all wheel drive) or 2 X

10kw wheel motors (front or rear wheel drive only), assuming a vehicle with four

wheels.

Any particular arrangement of drive motor-wheel layout may be decided by

production capacity, cost, performance or indeed a multiplicity of applied

criteria.

DIRECT CURRENT MOTOR EXAMPLE WITH MECHANICAL COMMUTATOR

To maximise weight savings and eliminate the need for two sets of brushes in a

conventional direct current application, i.e.

to supply field and armature windings, it is desirable to use a ring armature

fitted in the wheel rim/motor-casing/yoke, to revolve around an arrangement of

field windings (with two, three, four, five, six, seven, eight, nine, ten, or

multiples and/or additions of these numbers of poles according to desired motor

characteristics) being fixed or located (by splines, pins, pegs, threads, keys

or similar) with or without a connecting metal spider, in such a way as to

prevent rotation on the stub axle/motor shaft, being a reversal of the way an

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM.Page 12

PATENT DESCRIPTION CONTINUED

electric

motor is normally employed, i.e. fixed casing and revolving shaft/armature (the

ring armature and central field poles/magnets general arrangement is described

in Ferdinand Porsche's patent of 1900 number 18,099 relating to an electric

motor forming the hub of a wheel). A hollow spindle/stub axle can then bring

current carrying cables to either an outward facing commutator brush arrangement

or to the central field windings, depending upon the particular wheel

arrangement (see diagrams of design examples).

It will be seen to be advantageous to bring the end wires from the armature

coils towards the centre along the spider/spokes/casing/central pressing of the

wheel, to give physical support to the wires, then towards a smaller diameter

commutator/collector where the wires will terminate in the normal manner by

being pressed into a slot and then soldered in position. The commutator brush

pick-up assembly is arranged in such a way that it can be taken away from the

commutator with or without the wheel and be self relocating.

That is to say, by virtue of radiused edges and a lead in portion of the

commutator collectors (usually copper) or before the commutator collectors, the

brushes retract into their respective guide slots, preventing the normal jamming

caused by sharp changes in profile and aiding assembly.

An alternative design has the brushes coming from inside and making contact

against the inside face of a commutator whose collecting metal segments are

fitted on the inside of a supporting ring, instead of on the outside as is more

usual.

This has the advantage that for tyre servicing purposes the wheel/armature/commutator

assembly may be taken from the hub, stator and brush pick-up assembly without

having to disconnect the brushes from the electric supply cables.

Direct current brushed machines are considered by some electrical engineers to

be out of date and potentially less efficient in converting electrical energy

into mechanical energy. But there are many advantages to this type of machine

stemming from the simplicity of construction, repairability and low-tech control

requirements. For example, isolated communities, without sophisticated

electronic test/service equipment will be able to effect all servicing

requirements that would be almost impossible with the software driven brushless

machines described below. Similar long term servicing problems of petrol engined

cars equipped with electronic engine management systems are now working their

way through the second hand car market, with those electronically equipped

vehicles drastically dropping in value and prematurely ending up on the scrap

heaps. This is of itself of some environmental concern.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 13

PATENT DESCRIPTION CONTINUED

BRUSHLESS DIRECT CURRENT MOTOR ADVANTAGES

Mechanical commutator switching limits the electromechanical power conversion

potential of the d.c. machine. Centrifugal force considerations and the need to

clamp onto securely, limit the diameter, rotational speed and length of the

commutator, although rotational speeds of 1,000 - 2,500 RPM for wheel diameters

of 16 - 30 inches may not present too much of a problem. The desire to limit the

thickness of insulation between adjacent commutator segments also introduces

design restrictions.

Many of the limitations are mitigated if electronic commutation of the armature

coils is applied. One immediate advantage is that the armature winding may then

be accommodated on the stator, in this case being secured to the

stub-axle/bearing spindle, with consequent easing of the problems relating to

insulating and securing the conductors.

The apparent need for slip-rings and brush-gear associated with supplying d.c.

exciting current to rotating main-field coils may be avoided by mounting a/the

exciting-generator or exciter on the common shaft. Thus, if commutation is

achievable without the need for interpoles, a very simple rotor assembly is

possible. On some wheel-motor applications permanent-magnet field poles may be

employed, also solving the problem. Using the latest rare-earth magnetic

compounds very powerful yet lightweight wheel-motors may be constructed.

Electronic commutation eliminates the chance of an arcing brush/commutator

contact. Assuming that the controlling semiconductor devices are able to meet

the switching duty requirements, overall dimensions are eased and

retarding/advancing of the commutator timing to improve the motors flexibility

may also be enacted through the same controlling/switching electronics via

software. Coil short-circuiting during commutation may also be eliminated using

electronic commutation and the number of armature coils normally needed to

reduce this short-circuiting to insignificance, may also be reduced to simplify

manufacturing and design complications.

ALTERNATING CURRENT OR SYNCHRONOUS MOTOR ADVANTAGES

The drive motors may be of the alternating current type, this design of motor

being theoretically potentially more efficient in the conversion of electrical

energy into motive force. A.C.

motors also promise greater longevity of service, as no commutator or slip rings

are required not only reducing complexity but also frictional losses. Speed

regulation and power application in this type of motor requires sophisticated

electronic circuitry, firstly to generate an alternating supply/wave from the

vehicle D.C. batteries and then to regulate that supply by frequency and/or

pulse modulation.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 14

PATENT DESCRIPTION CONTINUED

It may be argued that the D.C. brushless machine and the A.C. machine described

above stray into each other's territory as both are in effect motors without

brushes operating from software generated waveforms and this is true. The

difference lies in the construction of the machine. For example, whether

permanent magnets or induced effect are utilised.

The motor wheel is of course designed with the facility of speedy servicing of

wheel bearings, brushes (where used), brakes and tyres. It can be seen from

examination of the accompanying drawings that none of the normal wheel and hub

servicing requirements are unduly affected. It must be recognised that the

system remains advantageous and workable no matter what design/type of electric

motor machine is employed in this capacity. Although it may be shown that some

designs and types demonstrate greater suitability to the application than

others.

It must be emphasised that this present wheel-motor invention relates to the

concept of incorporating an electric motor machine within the structure of a

modern road wheel/hub/axle assembly and in no way restricts the invention to any

particular type or design of electric rotating machine, but by giving example

and description of certain types, in particular the D.C. machine by way of the

suitability of D.C.

machines to tractive (motor vehicle) applications, endeavours to make it readily

apparent to the reader the basic requirements of/for the system to work

effectively.

2) DIRECT DRIVE - routing/transmitting power by shafts from a single motor is

eliminated and reduction by gears can be cut out of the drive train because of

inherent electrical wheel-motor torque characteristics, so improving efficiency

and saving more weight. Drive may be distributed to two or four wheels simply by

having motor units built into the desired number of wheels. If motor speed down

gearing is necessary in a particular (heavy duty truck) application, hub or

wheel rim reduction by an epicyclic arrangement would still enjoy a considerable

efficiency advantage.

3) FEWER MOVING PARTS - with electronic solid state switching and speed control

of the motor only the tyres, shock-absorbers, wheel bearings and commutator

brushes (if used) suffer from frictional wear (plus gears if incorporating heavy

duty hub/rim reduction). Brake pads and/or shoes would be the only other

mechanical item requiring service and as this is also part of the wheel/axle

assembly, maintenance of the vehicle, taken as a whole, can be seen to be

minimal.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 15

PATENT DESCRIPTION CONTINUED

4)

HIGH TORQUE - being improved with large radius field and armature windings,

making the most of the available wheel rim space. Additionally, the torque and

drive power of each motor/wheel is multiplied by the number of driven or

motor-wheels to give the total vehicle drive power and start off torque. In this

way four driven wheel units would be the equivalent of a very large and heavy

single electric motor, with the advantages that a number of smaller units have

an increased surface area giving superior cooling characteristics to the machine

for extended longevity and performance, apart from any torque considerations.

The winding insulation life-span may be extended beyond 50,000 hours as a result

of cumulative advantages and heat sink or liquid cooling techniques.

5) TWO MOTORS IN ONE - the adjustable commutator brush/pick-up unit/assembly

allows greater flexibility to be obtained from any fixed winding configuration,

by adjusting the commutator timing, effectively tuning the motor to a speed or

torque requirement and extending the flexibility that would otherwise be

impossible using power control alone.

6) NO DIFFERENTIAL - is necessary with any of the drive arrangements described

in normal operating conditions, further simplifying the system. Each motor

tending to adjust itself within acceptable limits to the rotation speeds of the

other motor(s) for cornering purposes.

If by reason of slippery conditions or loose surfaces, differential effect, or

tracking control and monitoring is required, a central microprocessor/computer

controlled, multi-channel speed controller can individually regulate and

synchronise each separate motor wheel for any particular cornering condition, to

optimise grip. To make this work, each motor wheel unit would feed information

from inbuilt transducers of load information and r.p.m., to the central control

computer/microprocessor. The information received would be compared with what

should be happening according to reference information and corrected as required

to maintain a stable course. Separate (matched) speed controllers (as channels)

will be required for each motor wheel, but it may well be that these separate

speed controllers are, by virtue of more readily available component values,

just as economical to employ than one large speed controlling circuit.

A different system of self-regulation can be used as a cheaper alternative,

possibly being slightly less effective in use as a differential system than the

microprocessor controlled system described above and by contrast a direct acting

cross linked analogue electrical control circuit, where one wheel motor takes

overriding percentage adjustment instructions of power application requirements

from the opposing axle wheel-motor, via what is essentially a balanced

apportioning system. Apart from any cost consideration this is the system that

is likely to be adopted for the mass market because it

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM.Page 16

PATENT DESCRIPTION CONTINUED is an easier system to implement and is likely to

be more reliable in service as it is possible to arrange the electronics to use

only one split channel or two lower output channels to give the same end result.

Each motor-wheel has its own speed controller. The speed controllers are

initially instructed in parallel equally by the driver operated speed control.

If one wheel speeds up in relation to its opposite axle wheel-motor, the current

drawn by that unloaded wheel decreases. A rotation speed sensing and regulating

circuit keeps each separate motor in % synchronisation with its opposite axle

motor, provided there is no change in load of one of the motors. If both motors

change loadings at the same time, as when cornering, sensors on each power

supply line detect which is drawing more and which is drawing less and provided

the changes balance each other within certain limits and the total flow remains

essentially equal as when driving the vehicle straight, then each motor will be

regulated according to the newly apportioned rotation speed.This has the effect

of providing an anti-skidding/overspin device that will keep the vehicle steady

on the course steered. The two separate power apportioning channels (one per

motor) may be considered/likened to a single axle-channel and divider/balancer/synchroniser

as it is posible to implement a single channel speed controller which provides

the same effect.

POWER SUPPLY ARRANGEMENT:

SOLAR CELL GENERATION

This present Wolverine system provides for collection of energy from nature in

the form of light converting photovoltaic cells or solar cells in the following

manner:

Solar cells are placed on the vehicle surfaces in such a way as to maximise area

and attitude for collection, without interfering with driver sight line or

vehicle functional components. Typically, five to ten percent (5 - 10%) of the

normal/average running requirement can be supplied directly in this way,

requiring three square metres or more of solar cells.

The solar cells charge an onboard electrochemically reversible cell/battery when

the vehicle is not in use (assuming an average for sunlight conditions). The

solar cells also contribute directly to power requirements when the vehicle is

driven.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 17

PATENT DESCRIPTION CONTINUED

When light levels fall below a level where the voltage output of the solar

collector components no longer provide any significant input, a circuit inserted

into/onto the system for regulation/disconnection purposes breaks electrical

contact.

This may be determined by a cadmium sulphide or similar light sensitive

resistive grid or other electronic component forming a sensor/transducer, one

way switching by diodes, or voltage drop regulated relays. Essentially, this

automatic electronic/electrical protection takes over, preventing discharge of

the power batteries and damage to the working components. The solar cell panels

are also overload and temperature protected in the normal way.

The solar cell panels are incorporated as lightweight structural plastic

sandwiches into, or as, the body panels of the vehicle, so forming the body

panels of the vehicle.

Design of the shaped panels is kept as simple as possible while conforming with

the aerodynamic outline necessary for efficient air penetration by the vehicle

form.

It would be an advantage if the combined solar-cells/body-panels were easily

detachable for servicing/repair. Some panels on a motor vehicle may be easier to

remove than others. A fixed roof panel for example, has to serve as a weather

proofing medium and wind deflector in addition to energy collection duties.

Sealing of the mounting edges will be paramount to the public acceptance of such

a system - we have all grown accustomed to leak proof cars with smooth edges.

Thus a mounting system which prevents leaks and provides a sound structural

assembly is a must. This may be accomplished with a light plastic or metal frame

onto which the solar-body panels fit mechanically and connect electrically.The

mating surfaces/edges of the solar-body panel may screw or clip onto the frame,

but the important sealing feature is a returned edge in the frame which doubles

back under a fixed panel to form a channel which collects and funnels water away

from the mating surfaces, so acting as a built-in drainage system. Panels such

as doors, bonnet and boot do not of course require much modification. However,

it must be noted that commonplace everyday vehicles already have lips, channels,

gutters and drains built into the design of the vehicle for just such weather

proofing and that these edges often form the structural joins of a unitary

design. Recent trends have seen the removal of external edges, seams or lips in

the interests of good airflow management.

Conversion efficiencies of solar cells at this time vary between 8 - 16%

depending upon the type, materials used and construction. With solar isolation

of 1kW/Msq (bright sunlight) and isolation in Great Britain of only 125W/Msq

(averaged over 8760 hours/year) This equates to between 10 - 20 watts output per

square metre respectively.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 18

PATENT DESCRIPTION CONTINUED

Multiply an output efficiency of 8% X 3Msq X 8760 hours and an average energy

contribution per car per year = 30 watts X 3 X 8760 = 262.8 kW/hrs. Now divide

262.8 kW/hrs by 15 to gain the number of fully charged battery-packs @

120 mile range = 17.52 X 120 giving a total yearly (annual) contribution from

the sun of 2102.4 motoring miles (21%).

The battery store from a battery powered electric vehicle provides the perfect

temporary store to complement solar assistance and make the system work. A car

equipped as per this example will save fuel costs of 39.74 per year @

1.89 pence per mile (average) on an electric vehicle, or 126.14 per year

(average) on a petrol powered car equivalent (battery charge efficiency @

90% overall has not been worked into the above calculations).

The very latest developments in thin-film and plated manufacturing techniques

have led to lightweight high-power cells which when incorporated as purpose

built body-panels, in the sandwich construction described, need not weigh more

than just the body panel alone (requiring no rustproofing) in a conventional

steel bodied automobile. If that is the case, there will be no undue weight

penalty imposed by equipping a vehicle with solar-body panel collectors, only

the drawback of additional expense.

The cost of producing solar-body panels may be reduced using sealed acrylic

plastic (or other transparent plastic material) in place of high transmisivity

glass, the loss of transmission efficiency being more than made up for by the

reduction of cost per unit and associated manufacturing difficulty.

Costs of producing solar panels on the scale needed for automobile manufacture

may be cut by as much as 70%, especially with the new plated method of

manufacture. The reason solar panels are so costly at this time is literally

because of the specialist market. For example, calculators powered by high-power

solar panels may cost X pounds for a basic model. Earlier battery powered

calculators would have cost the same, but the cost of purchasing new batteries

would probably have cost half the price of the original item and will need

replacing again and again on a regular basis.

Because the solar panel has been included in the manufacturing process of the

calculator, the price of the solar panel included has dropped dramatically. The

problem is only one of scale.

Using this method of solar energy collection and control, energy can be supplied

by direct onboard sunlight conversion to annually cover 20 - 40% of an estimated

average mileage of 10,000 miles, i.e. the equivalent of 2,000 - 4,000 free

motoring miles every year. The remainder can be topped up by fixed/stationary

external collectors or mains electricity

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Pae 19

PATENT DESCRIPTION CONTINUED exchanges when the vehicle is at its home base, or

any overnight charging station. Spare packs can continuously charge at home and

in addition to collecting and charging from onboard vehicle and domestic

electricity supplies or roof mounted domestic collectors, power-packs can be

exchanged at a charging station.Additionally, either of the optional compact

generators described below will allow the use of another fuel type, adding

greatly to the versatility of the system.

ELECTROCHEMICALLY REVERSIBLE BATTERY OR POWER-PACK STORAGE

The power-pack battery bank or electrical store of this present Wolverine system

must be of sufficient size/capacity to give realistic vehicle ranges for

commuting and other medium range operation when weather conditions are

unfavourable and prevent useful contribution from the solar collectors. The

battery store and continuous output rating must also be adequate to sustain

motorway endurance over the distance. Realistic ranges will vary according to

intended vehicle use/application, but can be taken for the purpose of giving a

specific example as being between 50 and 300 miles.

This will require the very latest storage cells giving high density charge

ratios. Approximate figures have been calculated as being between 400 - 1,000

pounds in weight and 3 - 7.5 cubic feet in size, depending upon the

electrochemical properties of the battery cells being used and the applicable

vehicle format. These example specifications should provide between 8,000 and

45,000 usable watt/hours, again depending upon the type of storage cells being

used. Multiples of these specifications would need to be applied for heavier

duty or higher performance vehicles. Development work on storage cells may in

the near future upgrade power to weight ratios, especially the sodium sulphur

beta cell being developed by the Chloride Group.

Provision is made within this present Wolverine system for smaller separate

battery store(s) to be contained within the vehicle structure for the purpose of

supplying a reserve, auxiliary or emergency energy bank/store. The reserve

batteries are also to be used for powering/manoeuvering a/the vehicle at times

of servicing/loading/refuelling when the main power batteries have been

unloaded/disconnected.

Because of the requirement for a separate onboard store or reserve of electrical

energy, the reserve or auxiliary batteries are an essential part of the system

and will obviate the need for temporary external connection(s) or other

manouvering arrangements.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 20

PATENT DESCRIPTION CONTINUED

MAINS ELECTRICITY CHARGING

This present Wolverine system incorporates and caters/allows for overnight

charging from domestic mains electricity supplies to bring the accumulative

battery of cells up to full capacity from, maybe discount metered supply

companies.

Or on a solar assisted vehicle setup, when overcast weather conditions may

prevent solar charging or where longer range use has exhausted the vehicles

batteries and time shortage dictates the need for this extra input.

The mains charging facility is well known. Sophisticated charging equipment is

available giving printouts of charging information, warning of battery condition

and automaticoperation of tapered charging cycles specifically programmed for a

particular battery type. At least four vehicle manufacturers use the technology

on cars that are offered for sale to the public at this time. The reason these

cars are not more popular is that direct mains charging alone severely restricts

the uses to which the vehicle so tied may be put.

Mains charging is a slow process as the current state of the art persists,

taking between eight and twelve hours-in most cases to fully refuel/charge a

battery bank. The time-swop or time-management possible with an exchangeable

battery-power-pack, as described below, is what makes this present Wolverine

system a workable and practical system.

Time management is a concept that has been recently accepted on a world scale

via the technology of the videotape recorder equipped with a timer. A person may

take advantage of the videocassette tape storage medium to store recorded

broadcast material when he/she is not at home to watch the item, and by so doing

manage broadcasting times to suit his/herself. The principle is much the same as

taking electricity at a time of greater economy, to suit yourself and also

shifting charging timespans to suit yourself. In effect you will be storing

energy and time. Time is irreplaceable.

Enquiries of supply companies into the laws and conditions covering distribution

of electricity in Great Britain suggest that there is scope for independents to

supply there own electricity via the National Grid at about half the price of

the domestic supply rate, currently 7.35 pence per kw/hr unit, tax free.

Unfortunately, VAT or it's equivalent tax will almost certainly be added by an

enthusiastic Chancellor of the Exchequer on top of the Fossil Fuel Levy (11%)

already imposed on electricity generating companies and passed down the line.

Yet there is no pollution tax on petrol engined vehicles.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 21

PATENT DESCRIPTION CONTINUED

Despite any obvious political hinderances there remains a lot of scope for a

specialist pioneer supply company to A) offer value for money against the

present electricity supply networks B) open up new profitable markets where

traditional suppliers would not bother and C) further reduce the price of

electric motoring for the consumer.

In effect the battery-power-packs of the growing numbers of electric vehicles

will form a gigantic mobile energy store or load levelling device for power

generating stations - at no cost to those utilities. It has also been calculated

that by storing energy from overnight generated electricity power stations will

be able to operate more efficiently by making better use of their plant.

Additionally, because the bulk of this extra generated electricity is made off

peak, there should be no problems associated with overloading of the existing

grid network as has been argued. It is all a question of management.

INSTRUMENTATION AND BATTERY PROTECTION

Because of the investment in a battery power-pack it is necessary to maintain

that pack or packs in the best possible state of charge or operating condition

in order to prolong the working life-span or number of efficient charging

cycles. For example it is well known that even especially designed deep

discharge traction batteries should not be drained below a working threshhold

where cell damage will occur. It follows that in almost every storage cell type

certain conditions must be satisfied to protect the battery of cells.

Most vehicle operators will not be familiar with battery requirements and so at

least basic automatic warning or other protection should be provided/included.

It is essential that at least a visible or audible warning be given to a vehicle

operator, when the vehicle's batteries are in a poor condition.

A more comprehensive/versatile warning device would be a gauge or LED or

preferably also an LCD display with or without audible signal accompaniment

which would show stored charge and warn when overnight charging is necessary and

alert the user as to any other precautionary steps to take and/or confirm what

action is advised. The same information gathering and processing electrical and

electronic package may also form an information display instrument or gauge

doubling as a battery condition indicator and energy remaining or fuel-gauge,

when the vehicle is in use, and the information of remaining charge also used

for corrective/adjustment purposes in any power-pack(s)/financial exchange(s)

transaction(s). In this way vehicles parked with drained battery cells may be

avoided, and battery-pack exchanges regulated.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 22

PATENT DESCRIPTION CONTINUED

This present Wolverine system includes for such an instrument or warning

aparatus one example of which follows:

The instrument hardware forming the heart of the system is/are an electronic

kilowatt/hour measuring device and display and a battery charge/condition

measuring device and display, capable of working with normal vehicle voltages,

e.g. 50 - 500 volts plus or minus 10%. Both of which may form part of the

vehicles normally required instrumentation, although the displays should be

clearly distinguishable to avoid confusion. (These electronic/electrical

measuring devices and displays being the equivalent of a petrol tank fuel gauge

and fuel flow meter on a petrol fuelled internal combustion engine driven

vehicle).There should be a separate battery condition display so that the

vehicle operator knows the state of charge of the battery pack onboard in

addition to the number of watt/hours used. The reason for this, is that the

battery capacity may vary with battery type/configuration as higher capacity

packs are inevitably developed and each pack (although of standard configuration

dimensionally) will have different safety threshholds if the batteries are to be

maintained in good condition.

The instrument should have it's own memory back-up battery which cuts in should

there be any interruption of the vehicle supply. The back-up charges itself

automatically from freshly exchanged packs, or when outside battery charging

(mains) is under way. The instrument may be assembled from standard commercial

electronic microchip components of 5 - 35 volts, and use dc-dc and voltage

sensing techniques and regulation to ensure low current drain, low leakage and

continued operation in isolation from long periods of non-use and between

battery exchanges. Some environment- hardening may be required.

The instrument may also operate at a higher level as an automatic warning device

for a number of possible errors or longer term problem areas associated with

wear, etc. LCD or other on screen messages or warning lights give advice to the

vehicle operator such as: "low battery please charge or exchange";

"defective battery pack - return to vendor"; "poor connection

between battery and vehicle drop and reload"; "check condition of

terminals".

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 23

PATENT DESCRIPTION CONTINUED

Each time a discharged battery-power-pack is exchanged for a freshly charged

replacement at a roadside forecourt/vendor (as in INSTANT CHARGING OR REFUELLING;

POWER-PACK FORECOURT

MECHANISED VENDING and BATTERY RENTAL SYSTEM headed sections below) the

following information will have to be exchanged: a) energy used b) validity of

battery number and hire agreement c) credit check and monetary adjustment. The

onboard instrument/processing system may also check the battery coded type,

serial number and log the time, place and location the exchange took place

together with the ammounts credited/debited.It may be desireable to include a

printout in-car (useful for checking accuracy of statements from the battery and

electricity supply companies), but this function, being more expensive, may only

be seen as an accessory on upper range models as a printout can be ordered from

any forecourt terminal. After an exchange the kw/hr meter resets to zero and the

kw/hrs used on that exchange is then carried forward only in the memory.

Having exchanged a battery-pack, a typical display might look something like

this:

ACCoUNT NUMBER10000001010 EXCHANGE NUMBER 062

OWN UNITS 1,421.66 EXCHANGE UNITS 1,858.23

OWN UNITS THIS EXCHANGE 1 0 . 60 UNITS THIS EXCHANGE 28.23

BATTERY CONDITION *** 5% *** MILES TRAVELLED 13,119.48

REGENEKATED UNITS 131 18 REGEN UNITS THIS BGE 0. 60

It follows from the above display example that the instrument will also have to

switch from measuring units used to units input while home charging, a role

reversal, then store the units supplied in a memory for later use.The own

supplied units will be deducted at the next exchange, so that the user only pays

the battery supply company for the energy they have supplied. Battery rental is

a separate billing, but the battery rental company will need access to

information of how the customer is using their battery-packs. The above display

example shows that this customer needs to refuel urgently and that their total

fuel bill @ 7.0 pence and 8.0 pence per unit respectively (own -

exchange) is 248.1 68 equalling a cost of 1.89 pence per mile excluding battery

hire. A 30kw/hr pack is used in this example and 120 miles is assumed as the

range per full charge (sports car example).

Battery depreciation can at this time only be estimated from information

supplied by manufacturers seriously intending to produce small batches of high

specification cell assemblies.

A conservative example of a sodium sulphur pack based on general budget

estimates gives the cost of a 15kw/hr pack @ 100 per kw/hr as 1,500.

This pack will give 2,000 deep

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 24

PATENT DESCRIPTION CONTINUED discharge cycles, 400 of which may be from cold

without damage. Thus 2,000 X 120 mile range = 240,000 miles.

1,500 divided by 240,000 miles = .625 pence per mile. Add the 1.89 pence for

recharging to the battery depreciation figure of .625 pence = 2.515 pence. Then

allow an extra penny per mile for the battery supply company = 3.515 pence per

mile. So on cost alone electric motoring makes sense, being 2.913 pence per mile

cheaper than (or almost 50% of) the average 6.428 pence per mile for a petrol

powered car (Battery charging efficiency taken as being 90% overall has not been

worked into the above calculations, neither is servicing included in any

example).

An electrical pulse triggered by or linked to wheel rotation via a counter acts

as a speedometer and odometer. This technique is well known. By cross

referencing the miles traveled, energy economy in miles per kilowatt hour may be

calculated and displayed. Likewise a running total may be memory stored (or the

calculation made from memory stored information when requested).

The onboard instrument must be able to transfer information to a/the forecourt

terminal. A simple way to achieve this would be by transferring battery exchange

information via a magnetic strip on a plastic (credit type) card. A card of this

type may double as user identification and one will be issued with every battery

hire agreement period - initially thought to be for periods of one year.

Some method of detecting unauthorised or expired cards must be built into the

system. This may be achieved by updating the database held at each forecourt

terminal or by direct link comparison.

FUEL CELL GENERATOR/CONVERTER (hybrid)

This present Wolverine system provides that additional power for long range use

may be supplied by a/an onboard fuel cell converter(s), converting hydrogen or

any other convenient convertible fuel in gaseous or liquid form. The fuel cell

conversion need only be required for extended range operation and it must be

remembered that where solar collector panels are fitted solar assistance is

always contributing to the vehicle power requirements when sunlight is available

- thus on average increasing vehicle performance overall. Because of the

increased cost of a fuel cell converter and possibly complicated (cryogenic

tank) storage system, vehicles used mainly for domestic duties need not include

this power source in their original specification, much reducing cost and

complexity. However, it should be made possible in the initial design to add-on

a Fuel Cell Generator at a later date/time.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 25

PATENT DESCRIPTION CONTINUED

To make it possible to realise the option of having the vehicle fitted with a

Fuel-Cell-Generator and at the same time increase the flexibility of the vehicle

format, the

Fuel-Cell-Generator/converter should be made as small and as light as possible

commensurate with the required power output for any particular vehicle

application, 500 - 3,000 watts being the range given by way of example. It

should be sufficiently compact and lightweight (50 - 100 lbs) to enable a person

of average strength to be able to carry it from the/a house to the/a car without

straining unduly, so making the

Fuel-Cell-Generator portable. The position where the

Fuel-Cell-Generator is physically locked on/into and connected electrically,

should be of a standard layout.By this it is meant the locking clips should be

placed logically and in the same position and spacing as in other vehicles using

the

Wolverine system/format. The interface support mountings and the insulated

electrical connections should also be in a standard position/situation with

respect to the locking mechanism and likely location in the vehicle. It must be

recognised that the location within the vehicle may be logically changed

according to intended vehicle type/use. The

Fuel-Cell-Generator may also have an integral storage tank, or a larger separate

tank, bearing in mind the safety storage requirements for this kind of fuel

system and this also should have mountings and connections of a standardised

format.

INTERNAL & EXTERNAL COMBUSTION ENGINE GENERATION (hybrid)

This present Wolverine system provides for a compact generator formed by the

close coupling of a lightweight petrol/diesel/alcohol or other fuelled internal

or external combustion engine and an alternator/dynamo which may be used to

provide a constant supply or pre-set options of output in the order of 500 to

3,000 watts. The generator assembly is/should be designed to be easy to carry by

one person (less than 100 pounds, ideally less than 50 pounds) and is either

equipped with an integral fuel tank or a reserve/holding tank and a separate

fuel tank of a larger capacity.

The motor of the generator should be designed to run at a constant speed; a

speed at which it more/most efficiently converts fuel via the generating

electrical machine to which it is attached, into electrical energy. The compact

generator is located in a position on the vehicle (such as in the boot or under

the bonnet) so as to be easy to load and unload. It will be desirable if the

action of loading onto the vehicle also plugged/connected the unit to the

vehicles1 electric supply/store/control-electrics/electronics.

B60 K & - COMPREHENSIVE ELECTRIC MOTOR ROAD VEHICLE SYSTEM. Page 26

PATENT DESCRIPTION CONTINUED

When the compact generator is fitted to the vehicle it would have the effect of

turning the vehicle into a hybrid, and give the vehicle the flexibility to run

on an additional fuel source in an emergency. It is intended that the portable

generating unit would not normally be used on day to day or commuting trips, but

only be taken/added to the vehicle for longer journeys or maybe used in

locations overseas where charging stations may not be so readily available and

local fuel supplies are all that is available.

The compact generating unit may or may not be equipped with self starting motors

and may or may not be equipped with a manual pull-type cord starter, both

options depending on intended application and the degree of civilisation at the

place of operation. The compact generating unit should also have the

standardised detachable layout described for the

Fuel-Cell-Generator unit above and should be interchangeable with that unit,